Nissan preps for next-gen LEAF EV production, but ‘a real challenge’ awaits

Nissan is preparing to begin production of the next-gen LEAF, which could happen as early as next March. Although work is already underway for the new EV, “a real challenge” awaits at Nissan’s Sunderland plant.

After ending production of the iconic LEAF electric car earlier this year, Nissan is preparing its Sunderland plant for a new electric era.

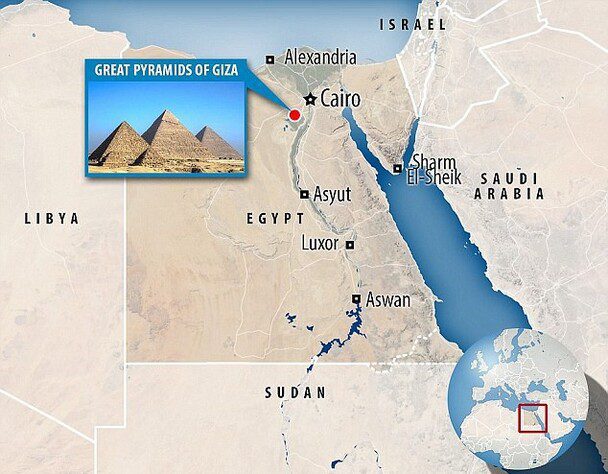

Although over 650,000 LEAF models have been sold globally, new competition has slowed sales. Nissan began building the LEAF at its Sunderland, UK plant in 2013, with over 280,000 built at the facility.

In November, Nissan announced a $3.8 billion (£3 billion) investment to upgrade the facility to build three new electric vehicles.

Nissan will build electric versions of some of its best-selling models, including the LEAF, Qashqai, and Juke. First up is the next-gen LEAF, which is expected to begin production trials in August.

With trials expected to run for six months, Nissan could begin next-gen LEAF production as early as March 2025. We could see Nissan’s electric car debut before the end of the year. However, that’s if everything goes smoothly.

After significant investments, Nissan is committed to building EVs in the UK. However, it is “not without its handicaps,” according to Alan Johnson, vice president of the company’s regional manufacturing.

“It’s a real challenge,” Johnson told Autocar recently. He added that building EVs in the UK “can work,” but only if “all the stars align.”

“When it comes to competing against other countries, there are a fair number of handicaps in the UK.”

Johnson referred to the lack of “good solid policies” and difficulties in building a regional supply chain. According to Johnson, the biggest challenge is the cost of energy. “We pay sometimes twice what is paid in mainland Europe,” which can drastically reduce profits.

Nissan is preparing for next-gen LEAF production

To combat higher energy costs, Nissan is boosting renewable energy use at the plant. Around 20% of the factory’s energy use (roughly 250 MW a week) is generated from on-site wind and solar farms.

Nissan plans to reach 100% renewable energy use, but no timeline is set. The plant’s upgrade includes a new battery factory to supply the next-gen LEAF and another gigafactory not too far away.

Engineering manager Guy Reid told Autocar that this is the start of a new era at the plant. However, Reid added, “Significant changes are needed to open up a line that has been building ICE cars for over 30 years.”

Like other automakers have found, new tech and machinery are needed to move the heavy weight of EV batteries efficiently. In addition, the plant’s staff is being upskilled for EV production.

“That creates its own challenges,” according to plant boss Adam Pennick. Nissan plans to expand its workforce significantly at the plant as it looks to ramp up output.

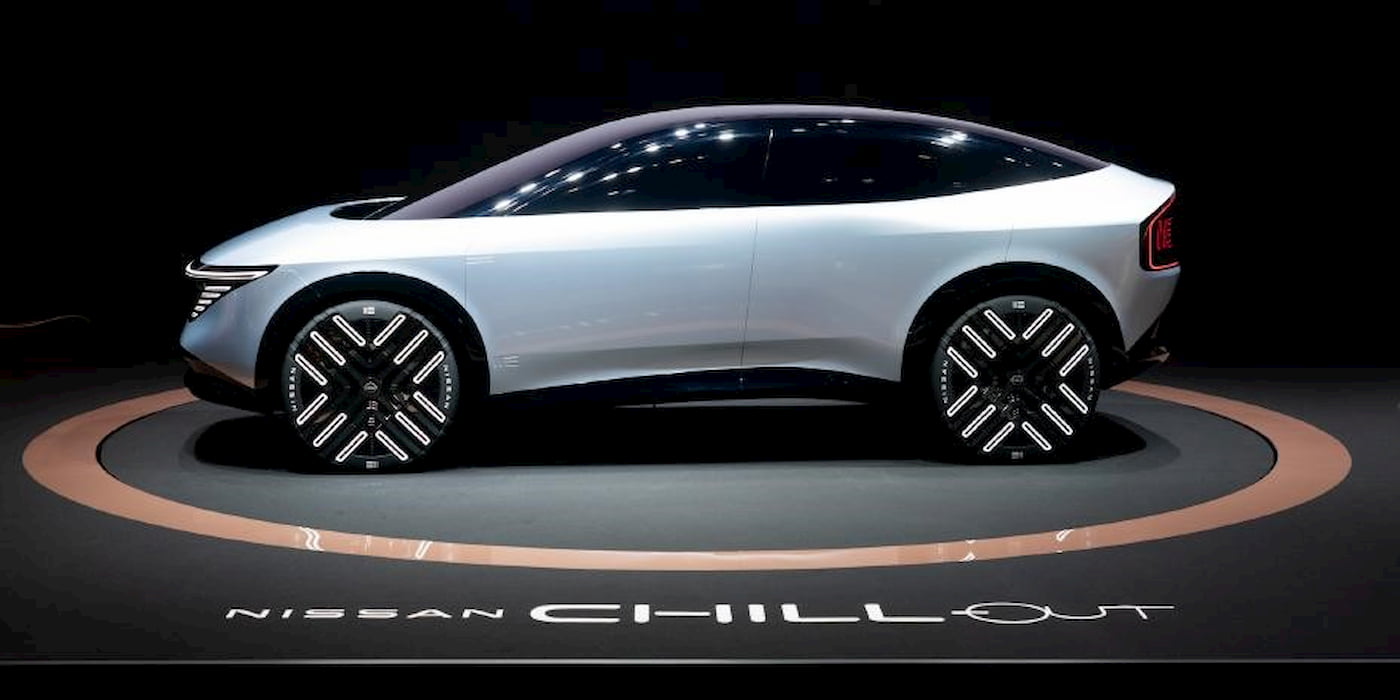

Nissan has said the next-gen LEAF is previewed in its Chill-Out concept. According to sources, it will be closer to a crossover coupe with a complete redesign. It will still remain smaller and sportier than the Qashqai and Juke.

One source said its design was closer to that of Ariya, Nissan’s electric SUV. Another source described it as a “mini Ariya.” Meanwhile, Nissan told dealers it will feature a radical design upgrade and pack 25% more range to make it more competitive.

Electrek’s Take

With sales of the current LEAF model falling out of favor, it’s time for an upgrade. LEAF sales are down significantly in every major sales market over the past year as new EVs hit the market.

Meanwhile, Nissan’s Ariya is picking up the slack. Through March, Nissan Ariya sales reached 4,142 in the US and 4,050 in Europe. With the next-gen LEAF’s debut in sight and two electric SUVs to follow, Nissan expects the momentum to continue.

What do you guys think? Will Nissan’s new LEAF revive sales? Let us know your thoughts in the comments.