Under Fire: Reevaluating Torch and Grit Testing Parameters – Charged EVs

The safety of Li-ion batteries relies on containing single-cell thermal runaway (TR) events so that they cannot propagate into adjacent cells, triggering a cascading failure. While the thermal energy released during a runaway event can take multiple pathways, the most significant are:

- Cell-to-cell conduction

- Solid-, liquid-, and gas-phase ejecta released from the misbehaving cell.

The first can be controlled with high-performance insulation materials which, when placed between cells, act as a firewall. As the world’s highest performing insulation materials, aerogel-based thermal barriers have effectively solved the challenge of cell-to-cell (C2C) conduction.

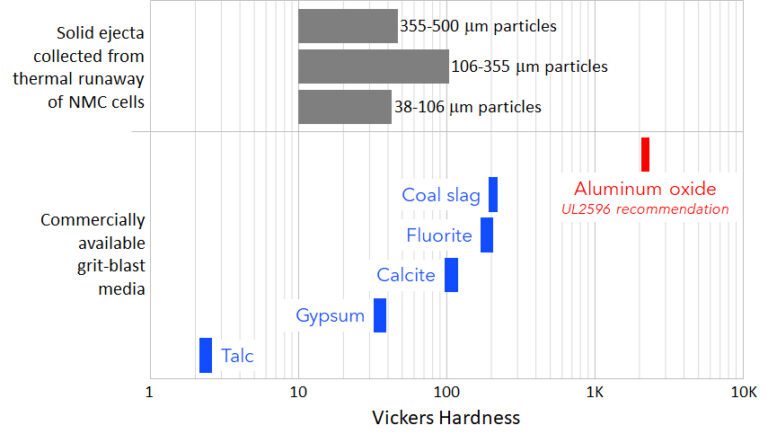

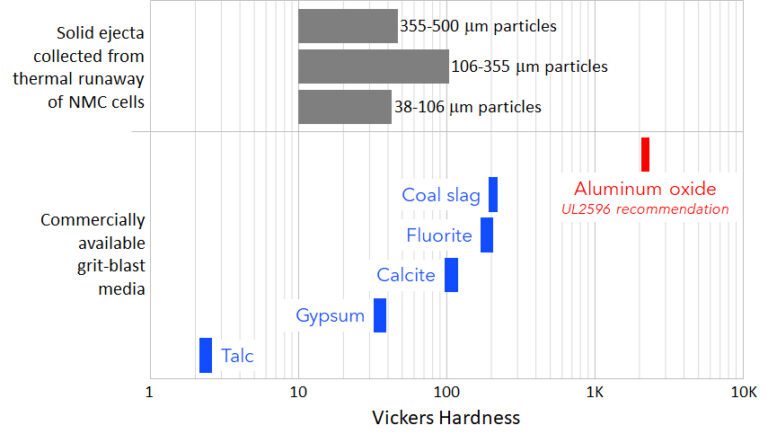

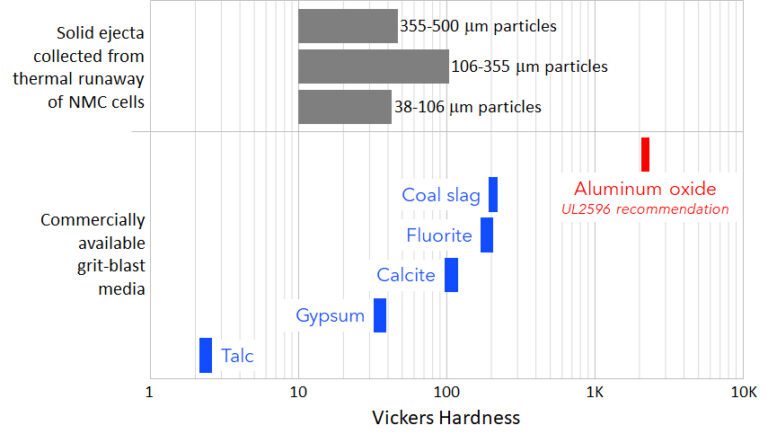

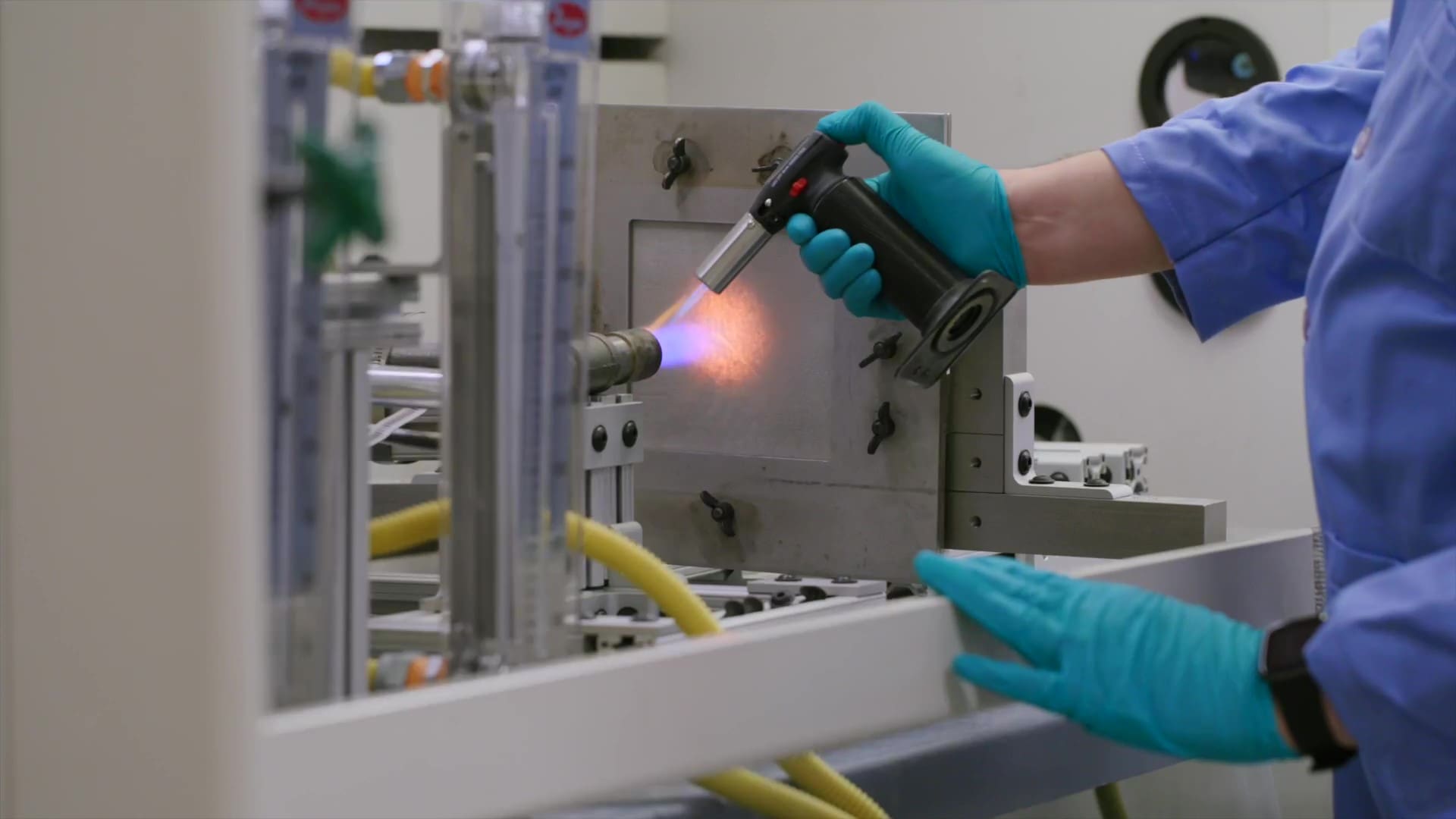

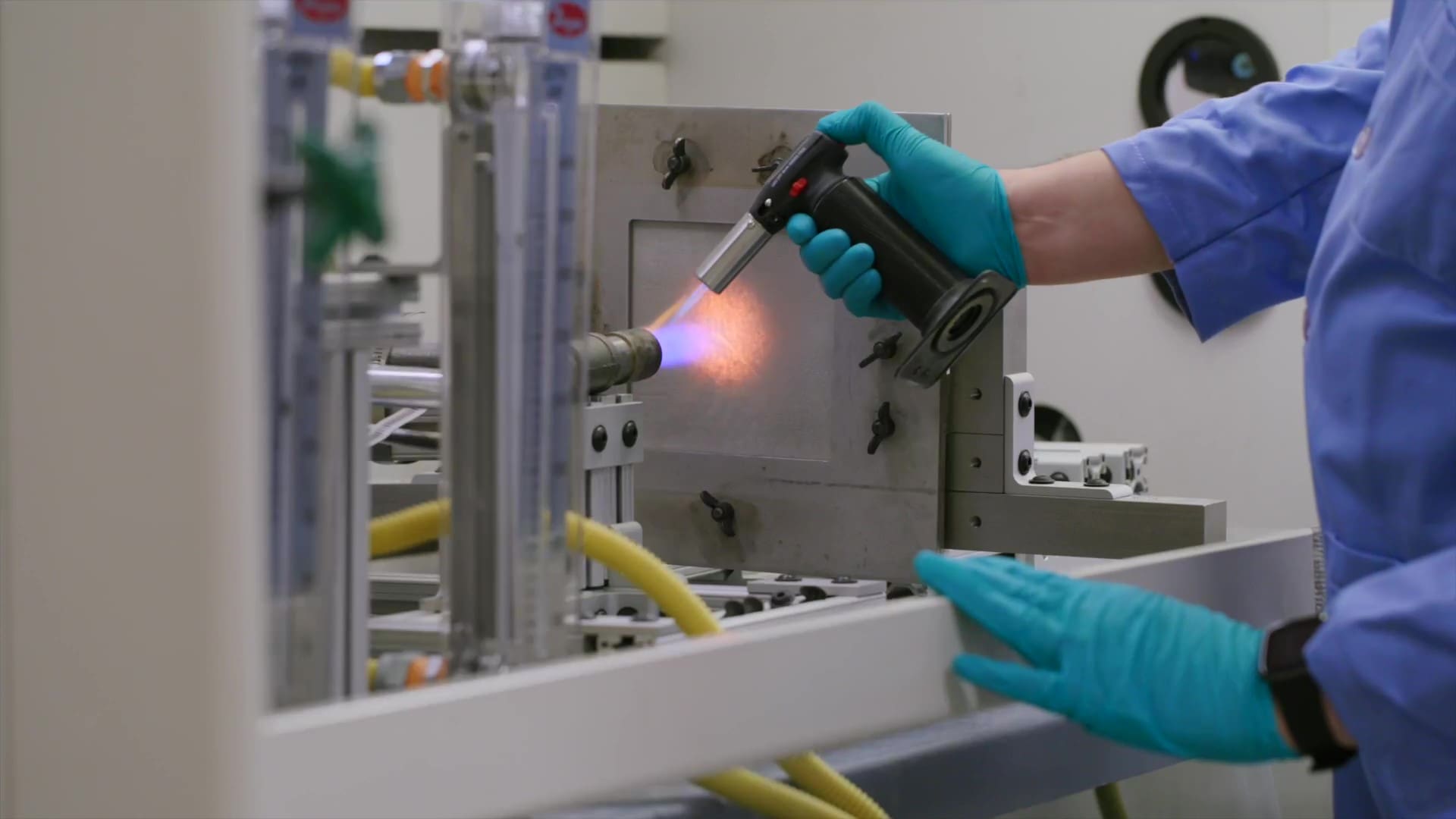

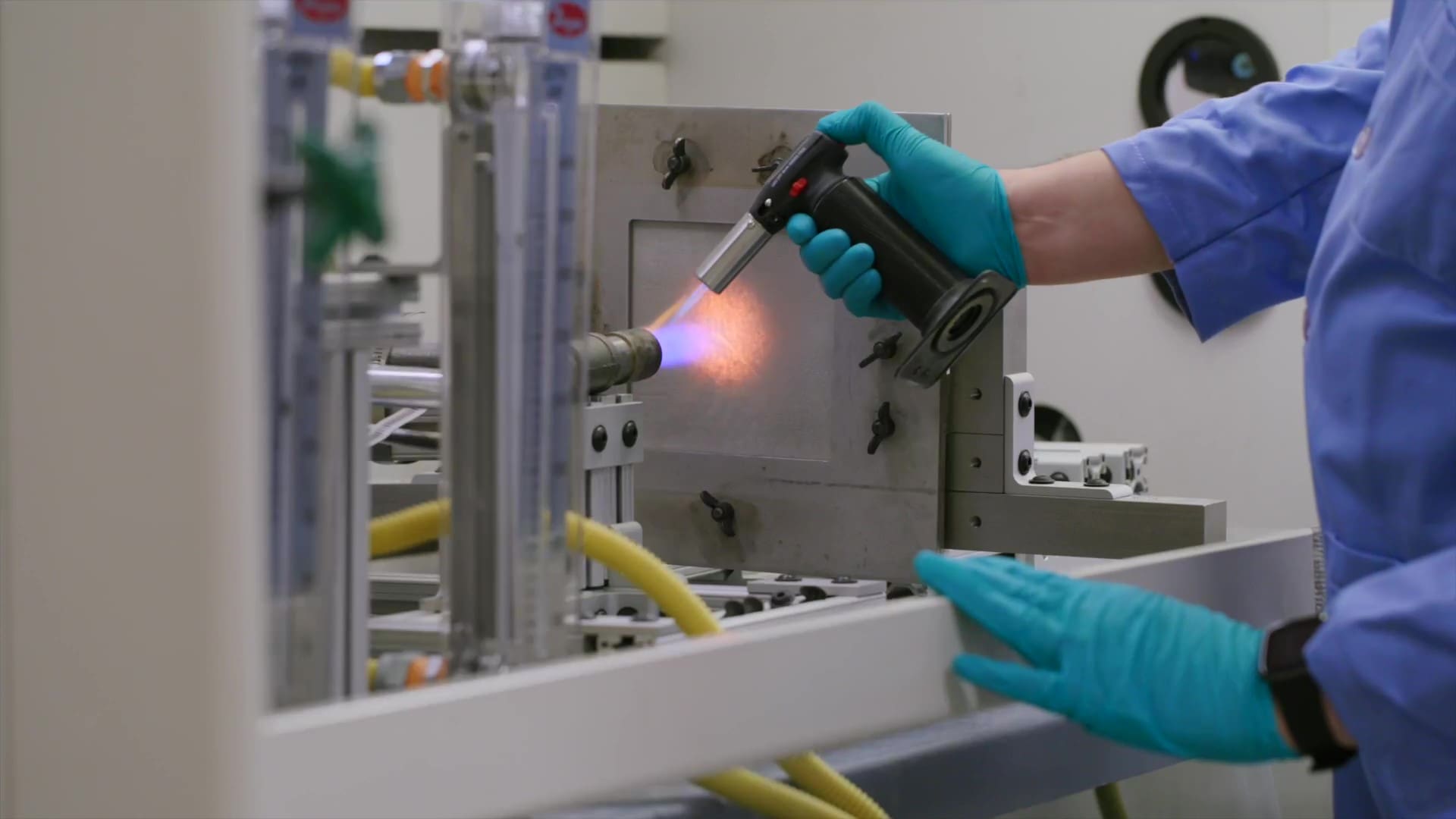

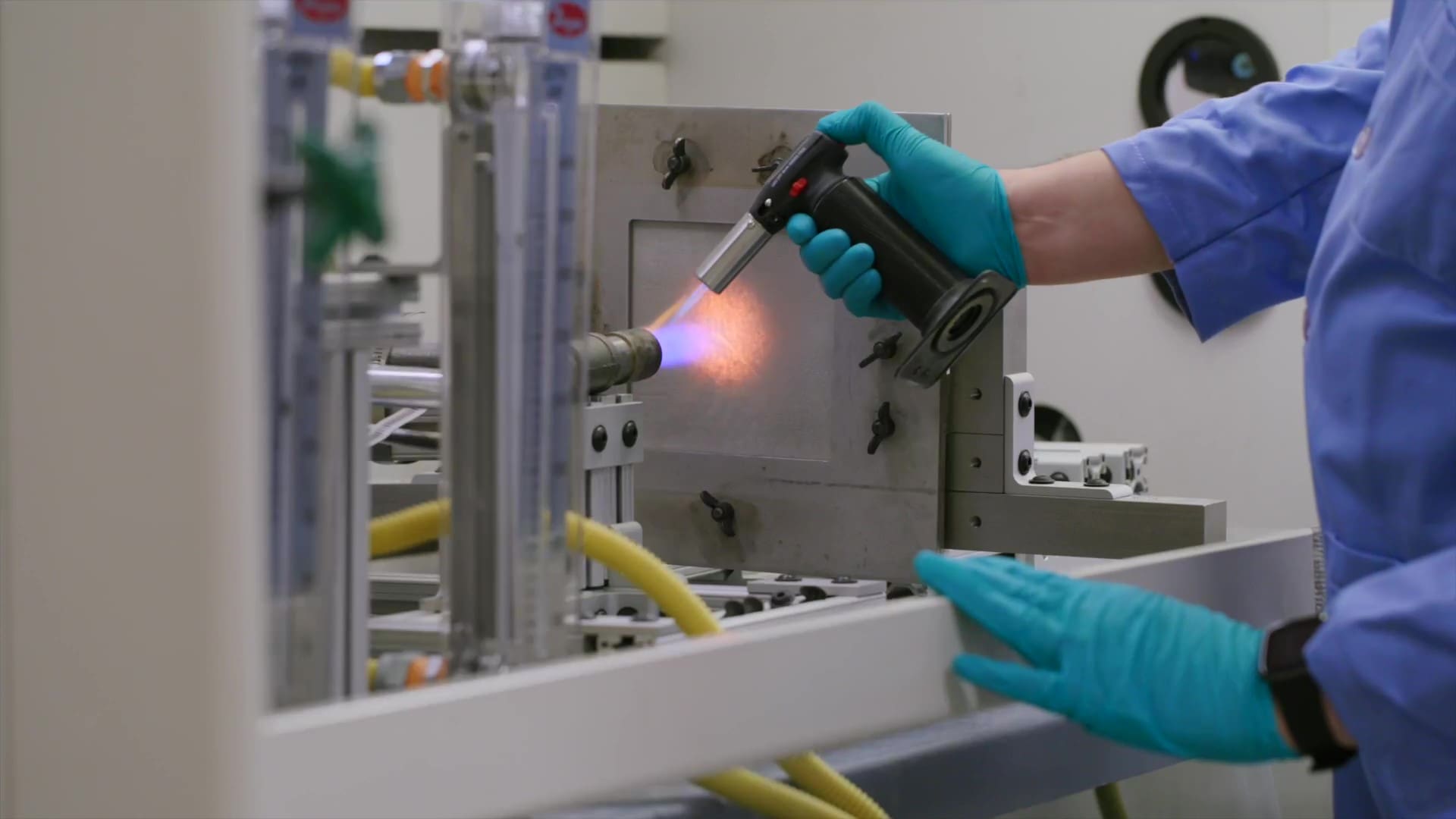

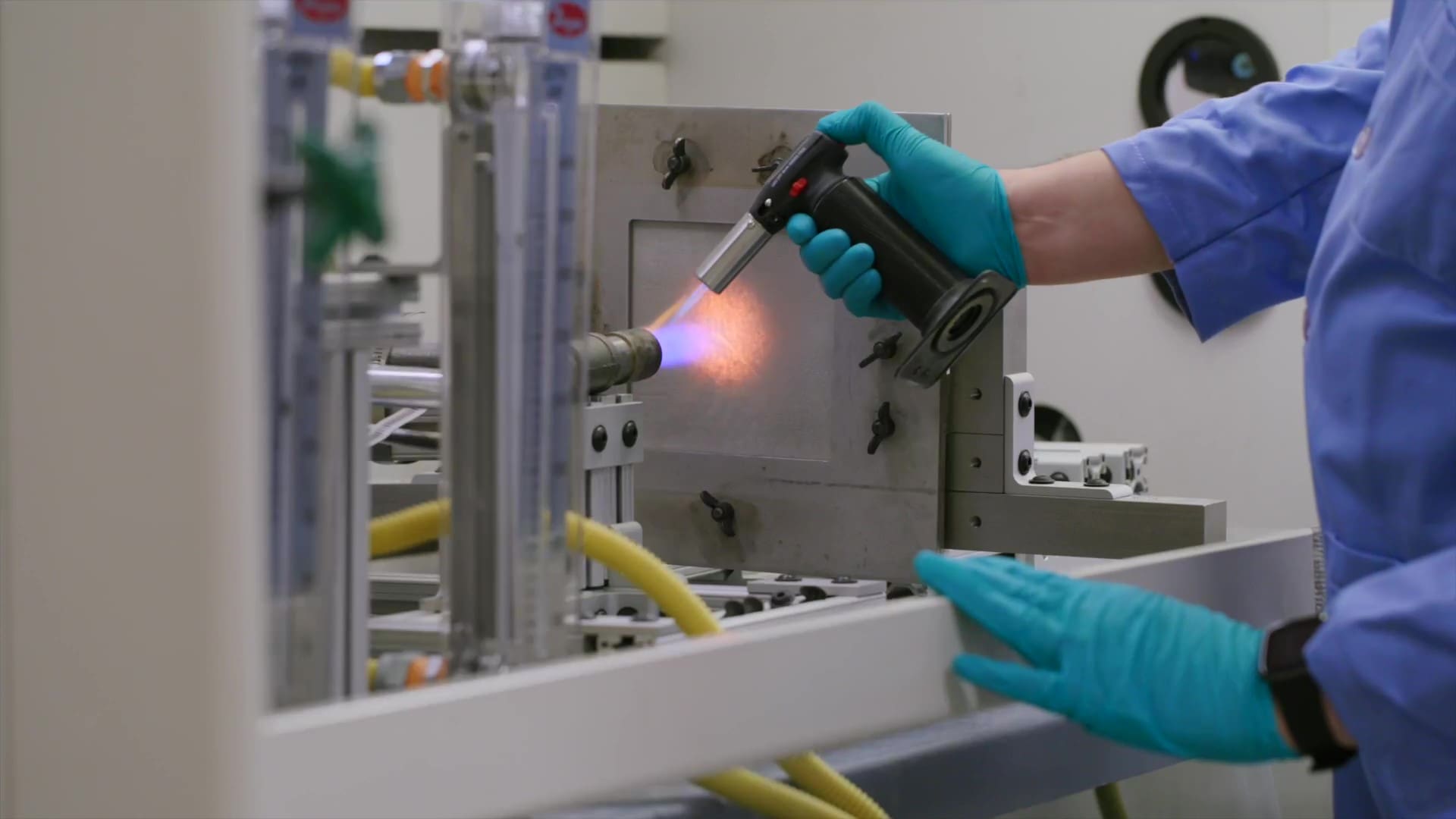

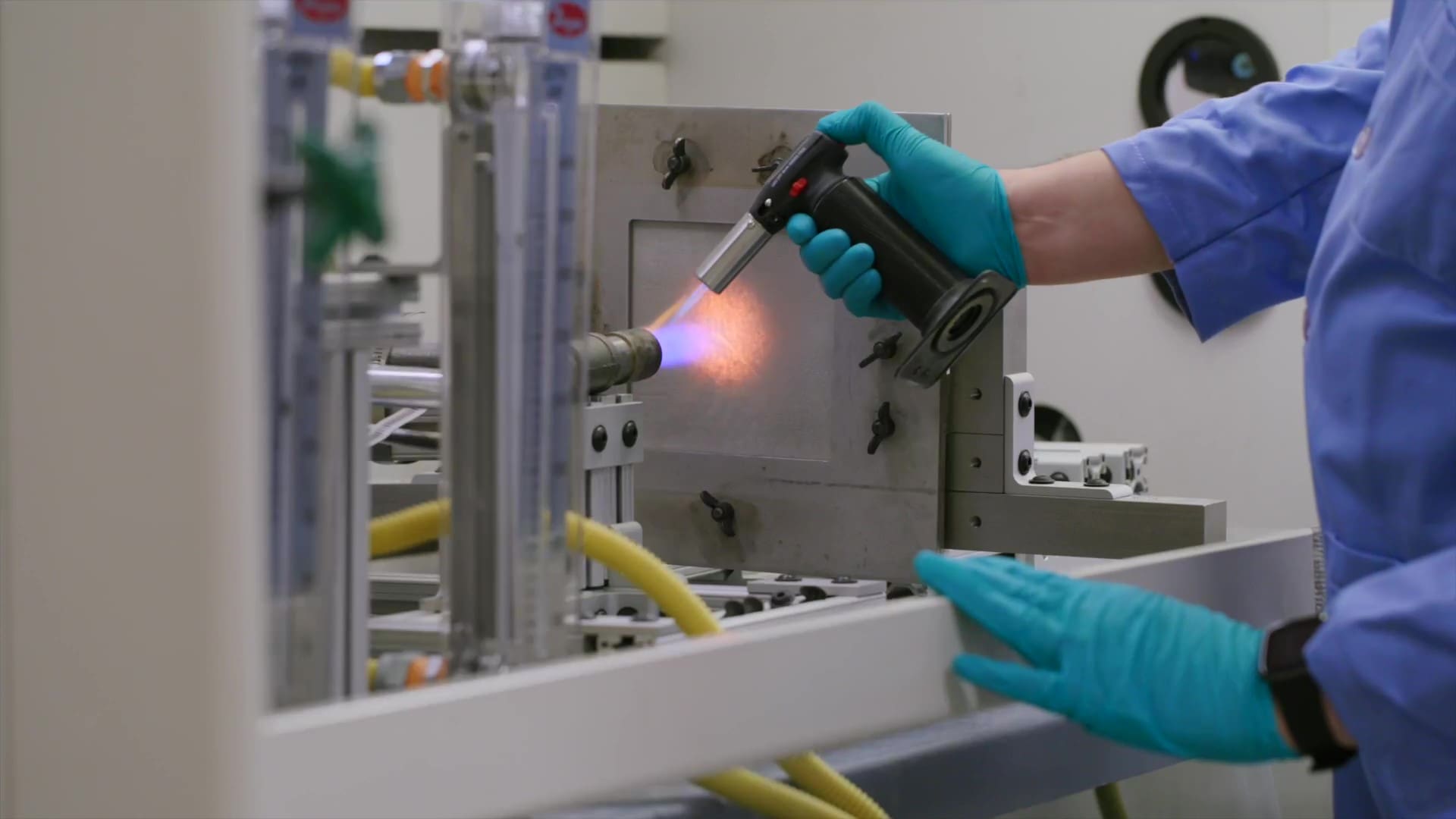

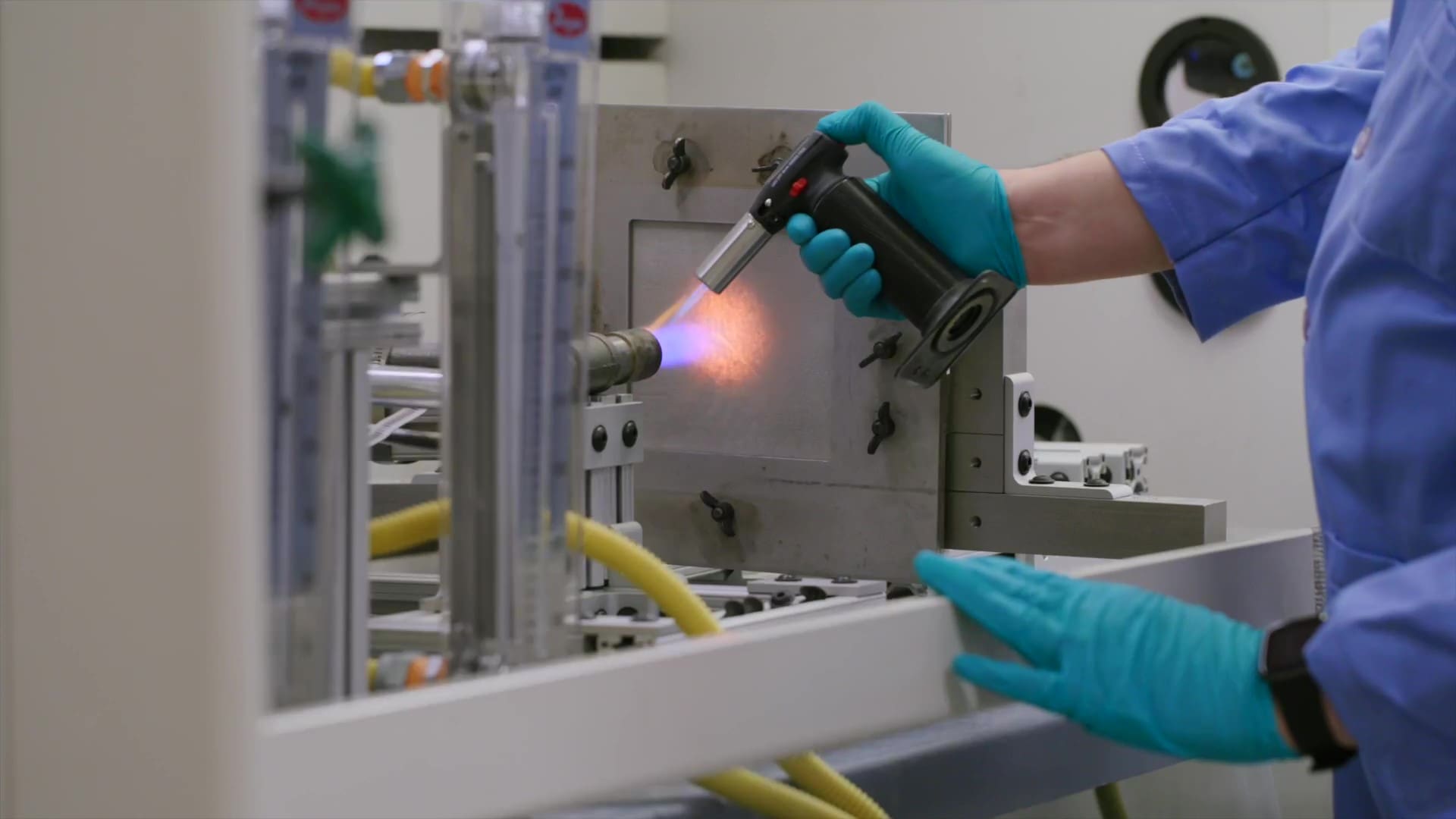

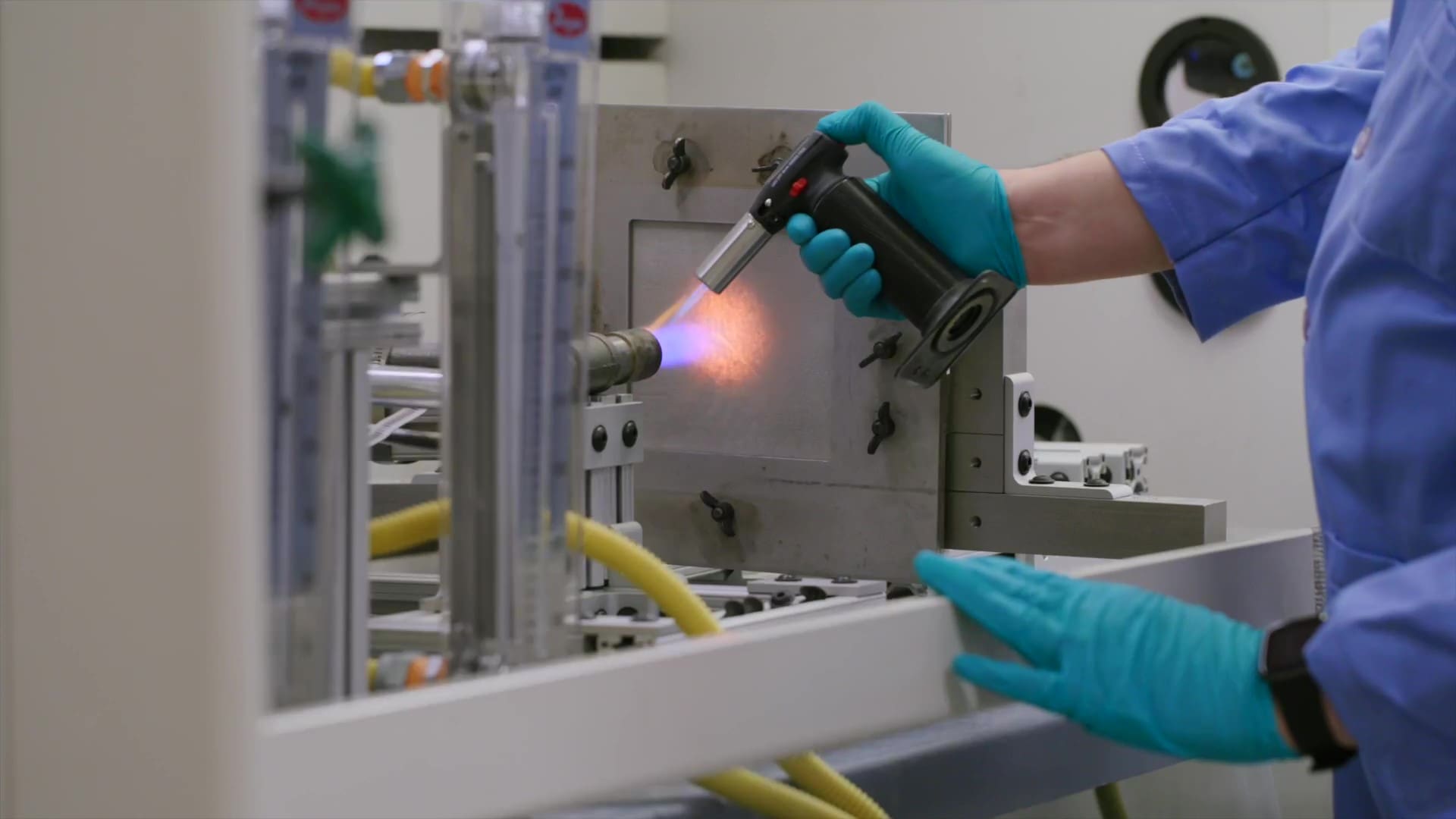

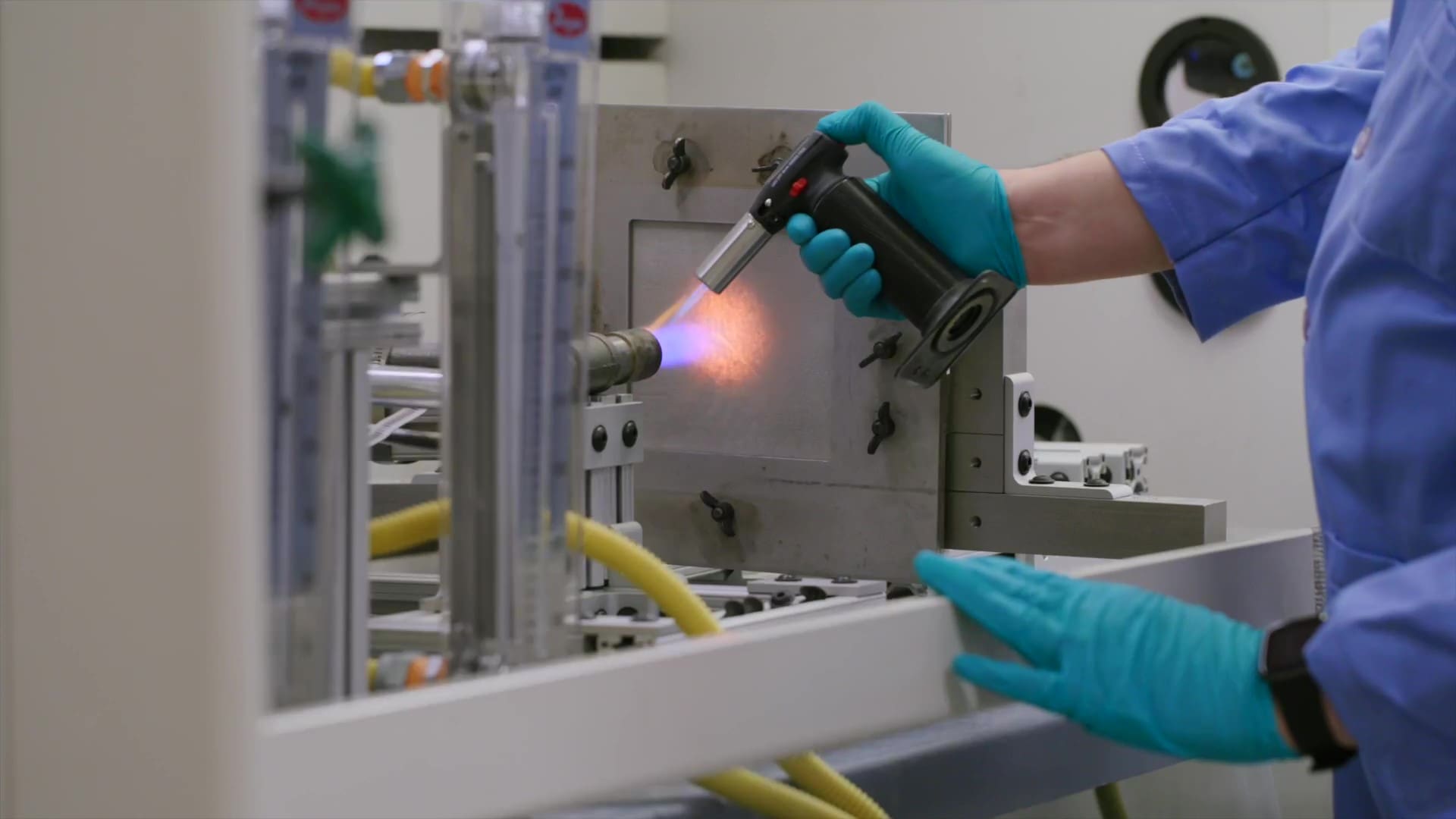

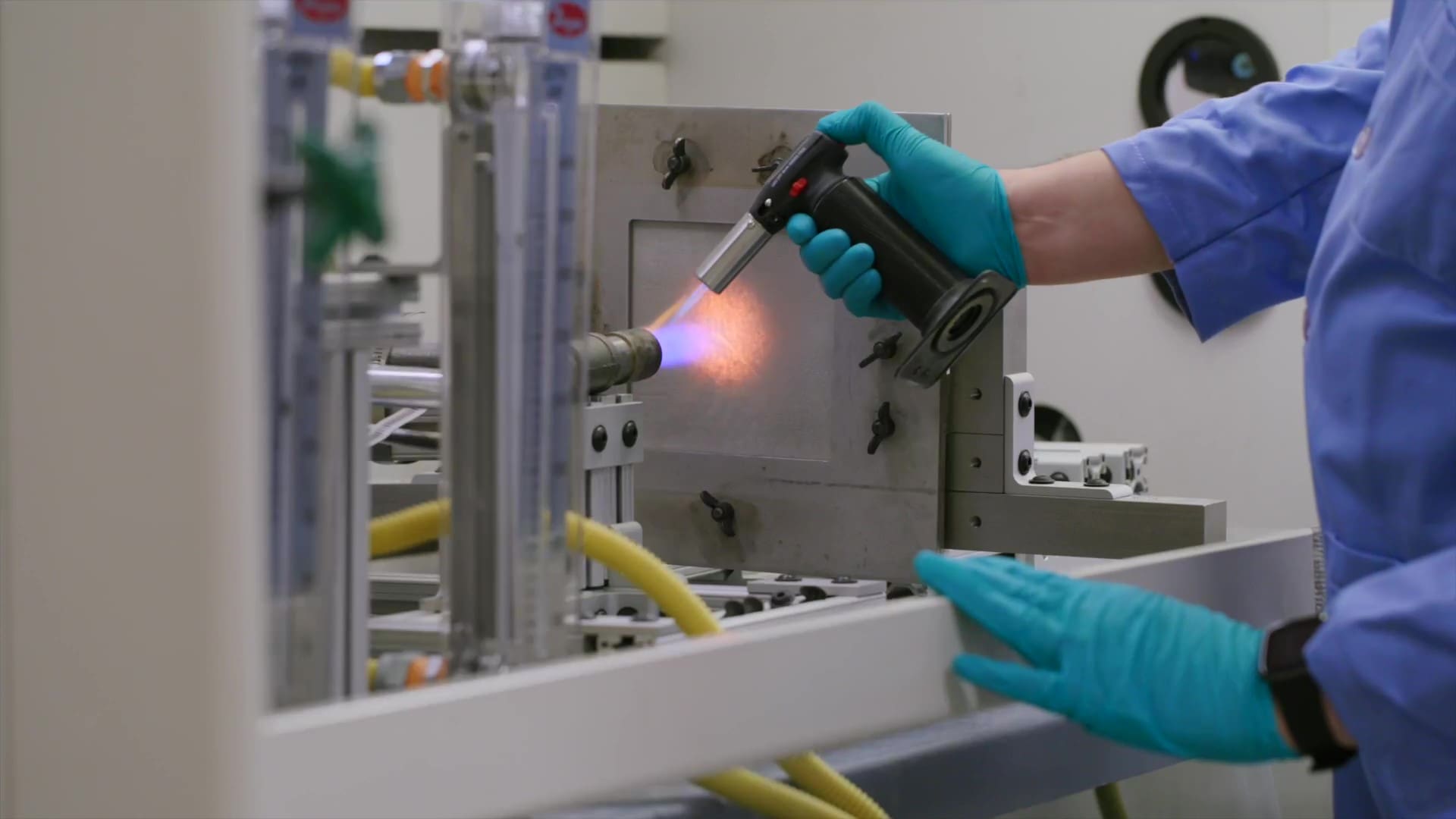

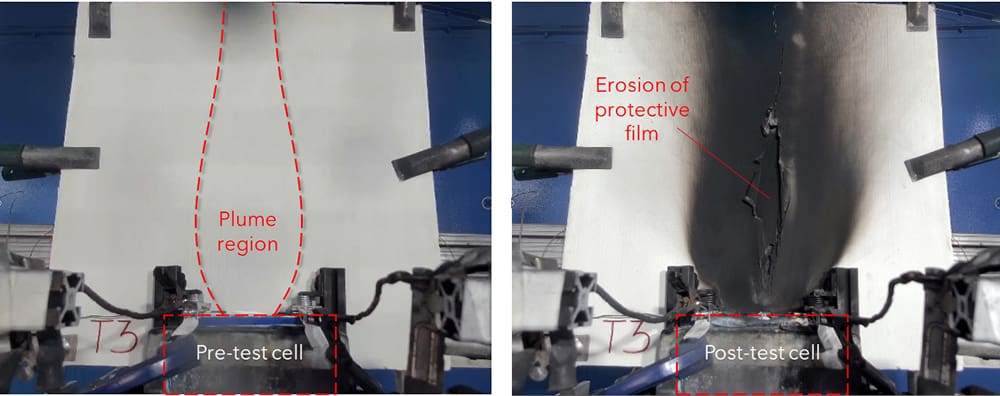

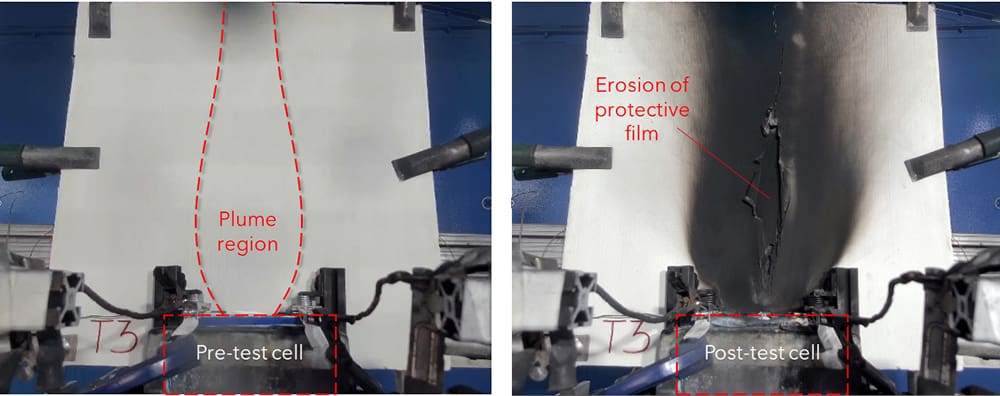

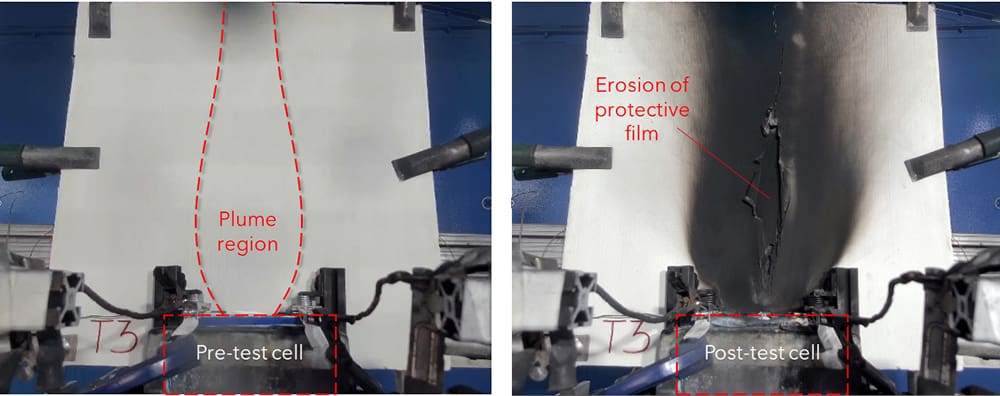

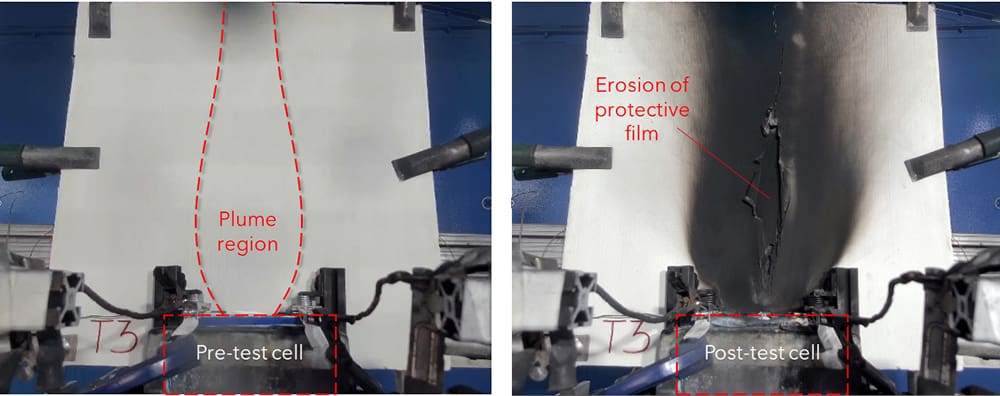

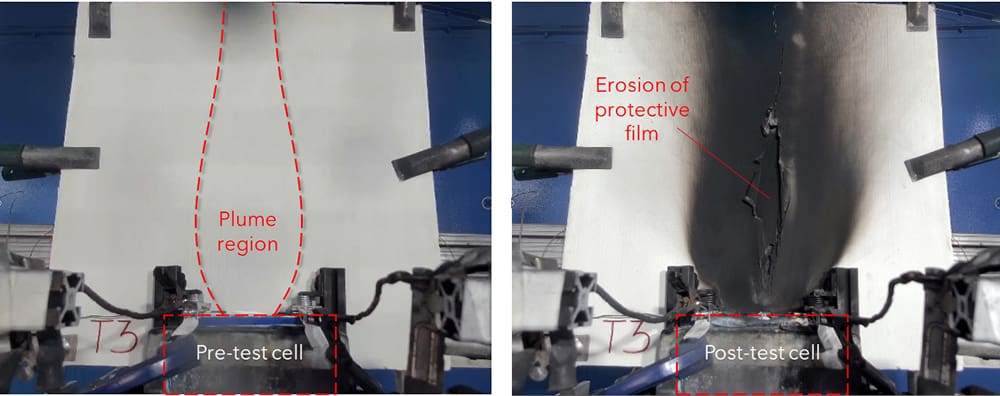

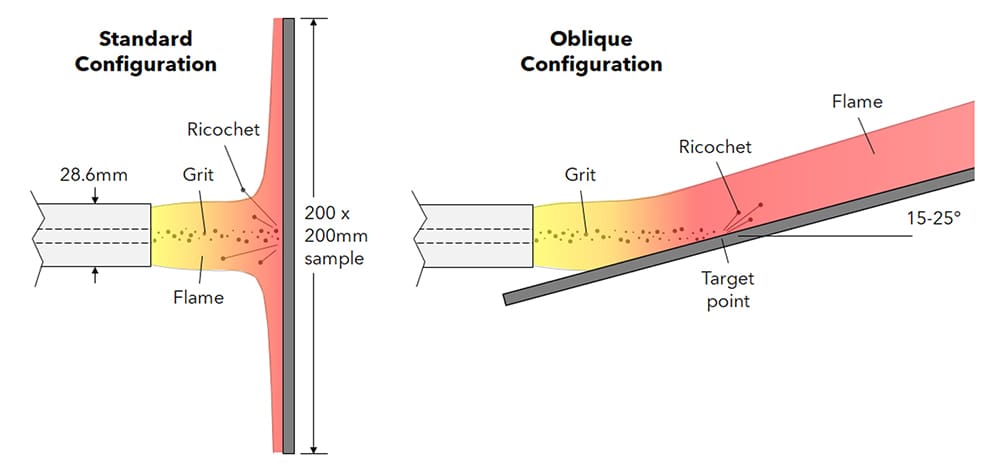

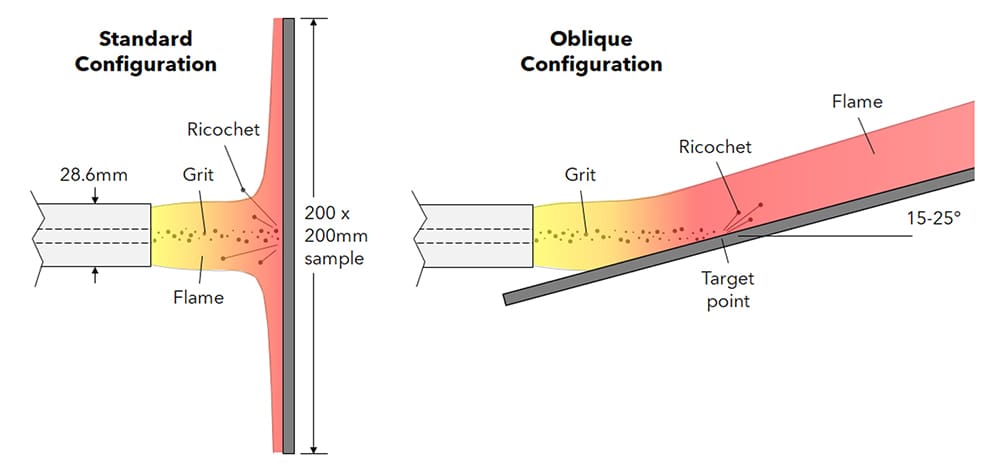

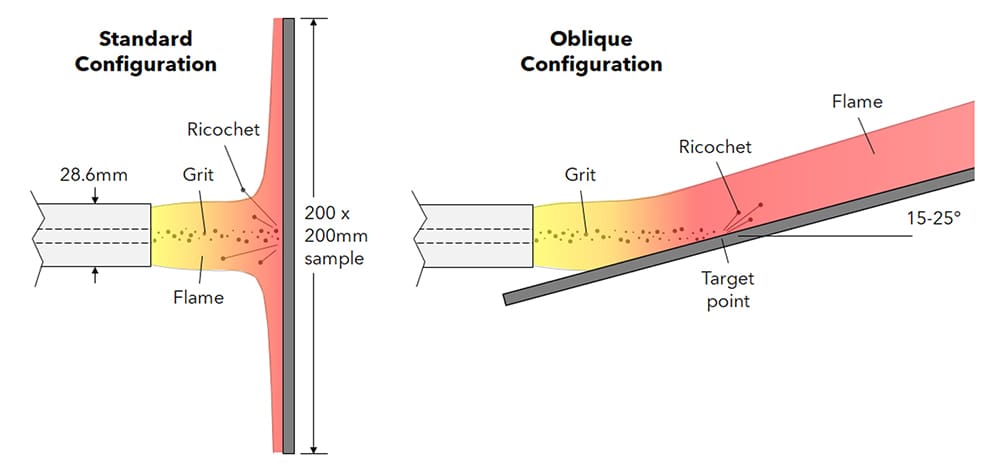

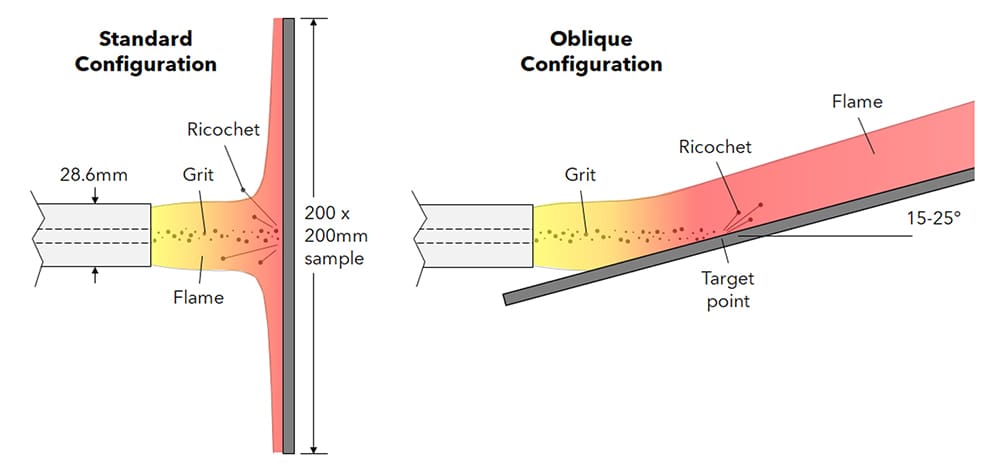

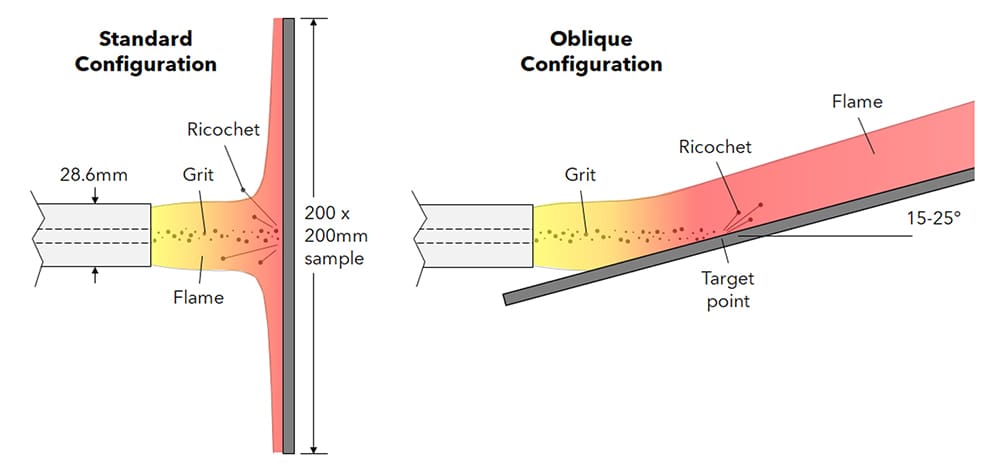

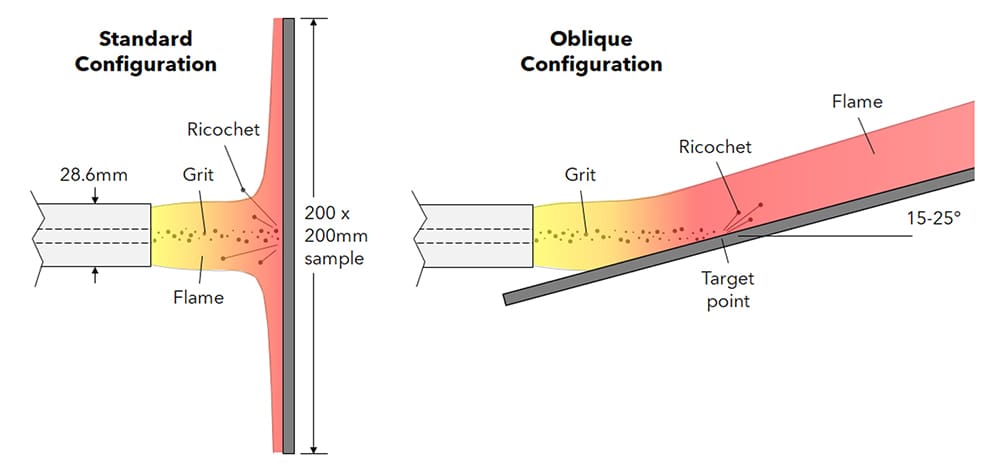

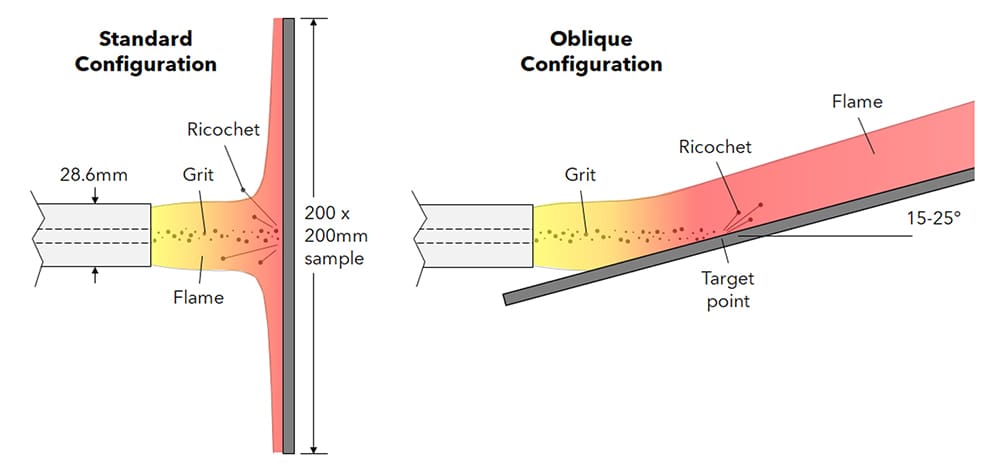

The safe dissipation of ejecta is a more difficult task. The high-velocity, high-temperature jets that emerge during a cell rupture can quickly melt and/or erode even solid aluminum. To better understand this combined thermal and abrasive assault, engineers often turn to the UL 2596 test standard for guidance. This method uses an array of burning Li-ion cells to assess the thermal and mechanical performance of battery enclosure materials. Recently, the standard was revised to include a benchtop experimental method of simulating exposure to battery-fire ejecta, but without the batteries. This new torch-and-grit (TaG) method directs the flame from a propane torch at a target sample, while periodically injecting high-velocity grit into the stream to replicate battery ejecta and their effects on adjacent components.

The UL 2596 standard has been very helpful in the evaluation of pack covers, which generally exist in close proximity with, and normal to Li-ion cell venting. However, outside of the immediate impingement zone, the UL 2596 test parameters are likely too conservative to simulate exposure throughout the rest of the pack. In other words, components that can survive module- and pack-level thermal propagation testing will often fail UL 2596, limiting its value as a screening tool for non-pack-cover applications.

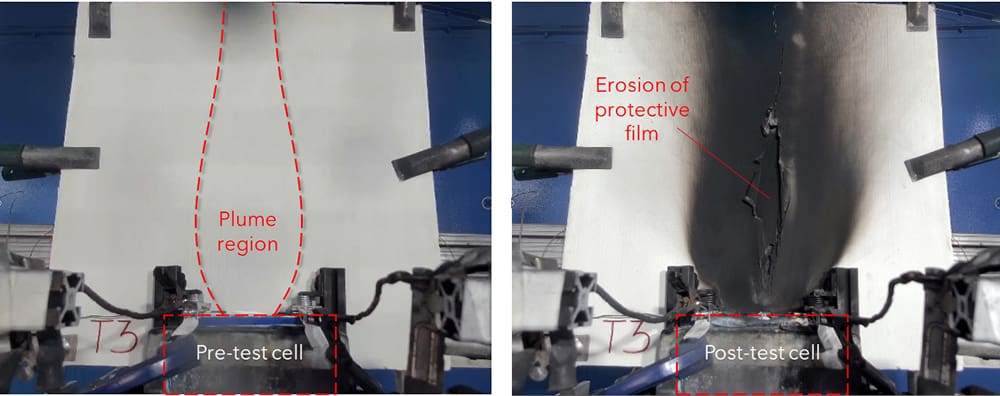

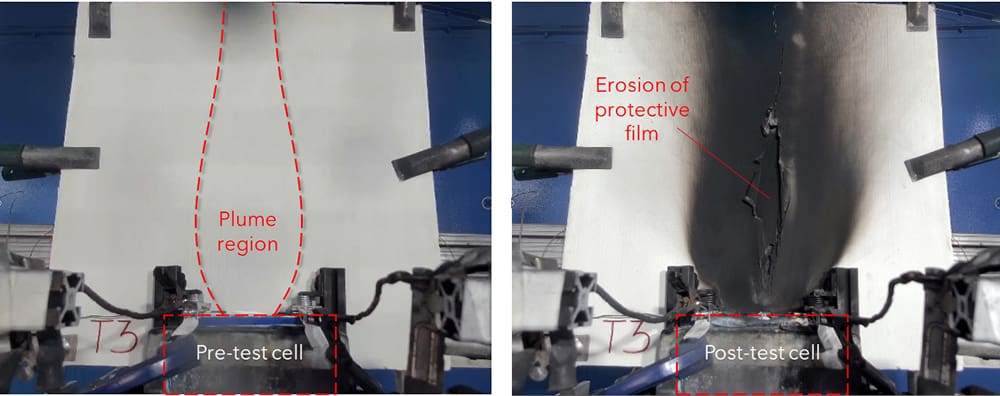

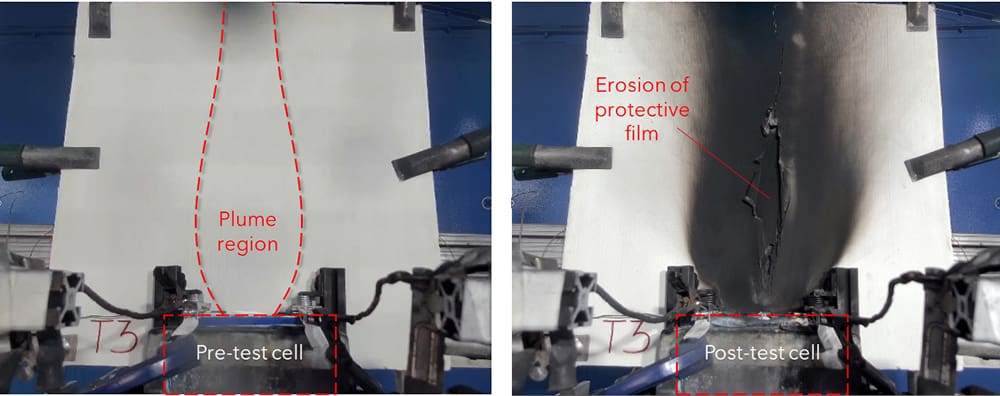

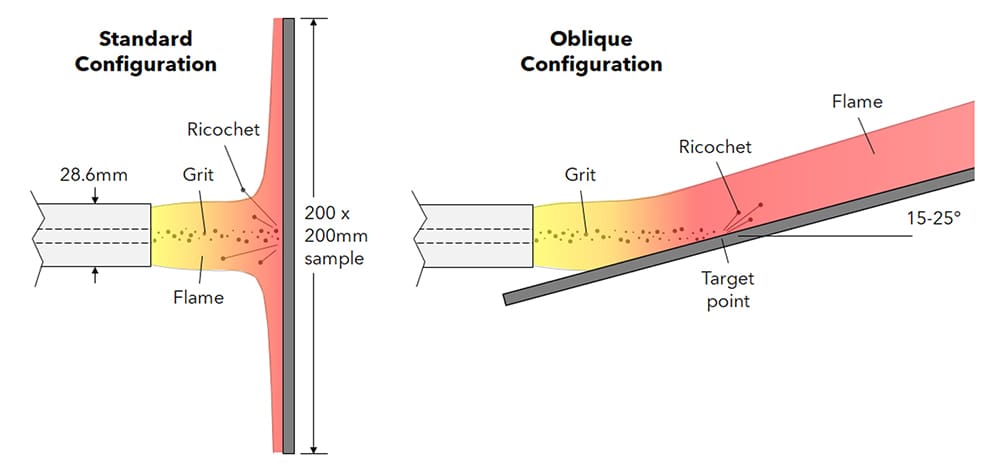

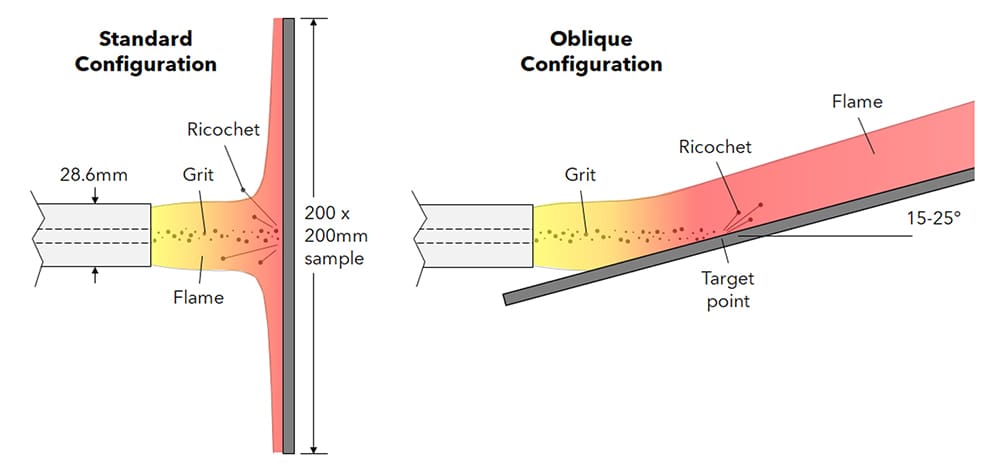

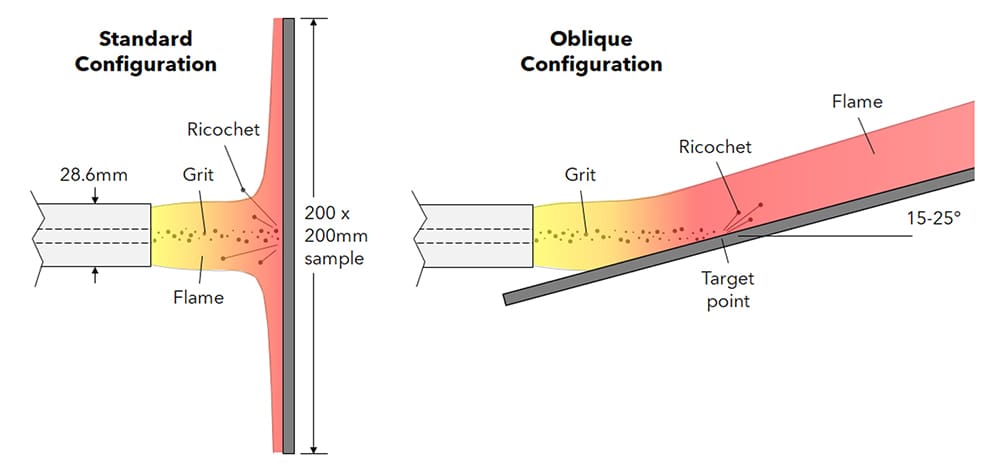

However, recent thermal runaway testing suggests that UL 2596 can be modified to improve its accuracy for non pack cover components. These tests placed prismatic cells directly against and parallel to a target sample such that, when triggered, the ejecta impacted the sample at an oblique angle. The resulting “glancing blow” was found to be more typical of what’s experienced by components farther away from the impingement zone. It also suggests that canting the UL 2596 target to 15-25° from parallel might provide a better simulation of far-field impingement.

After each test, the ejected solid particles were collected for analysis. The team reviewed the particle size, hardness, and chemistry to better understand their behavior during thermal runaway events. The analysis revealed a significant proportion of large (>700µm), non-spherical remnants of aluminum and copper foils. While their initial ejection velocity is high, the multiple inelastic impacts they experience within the confined space of a battery pack quickly bleed off momentum. The resulting crumpled pieces possess a low ballistic coefficient and will subsequently follow the fluid-dynamic streamlines toward the pack vent – think feathers, not cannonballs.

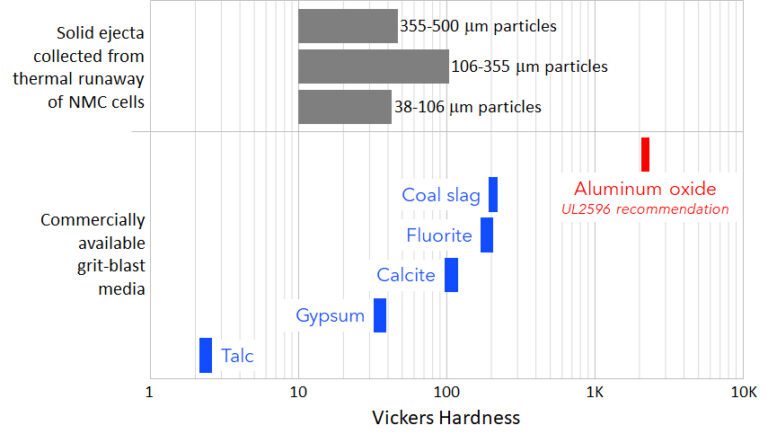

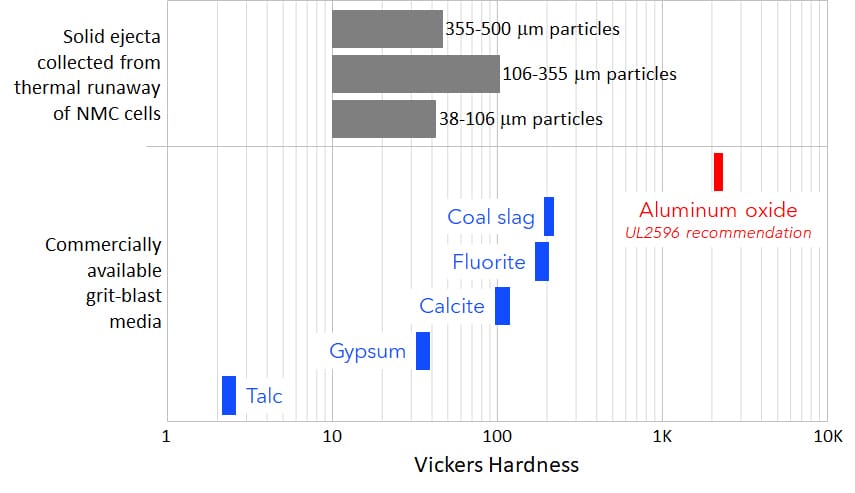

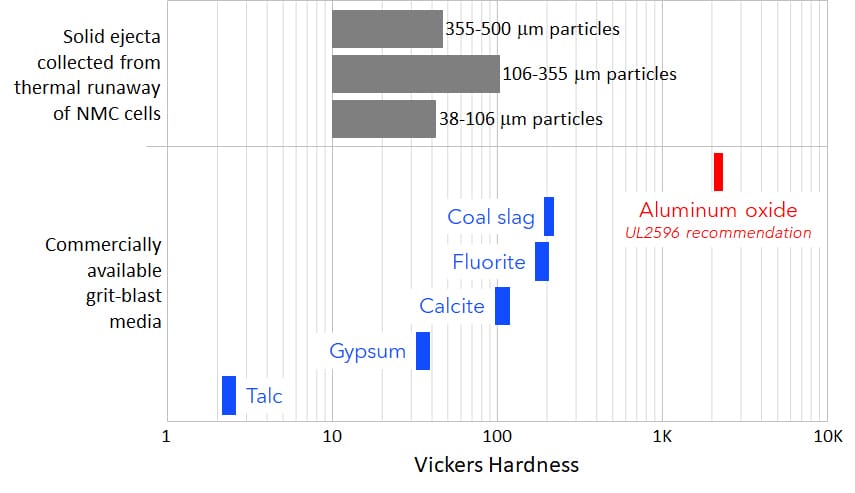

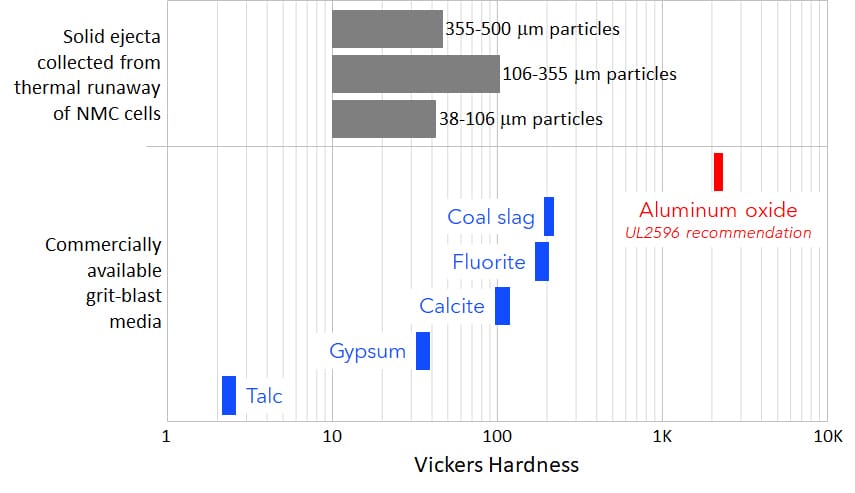

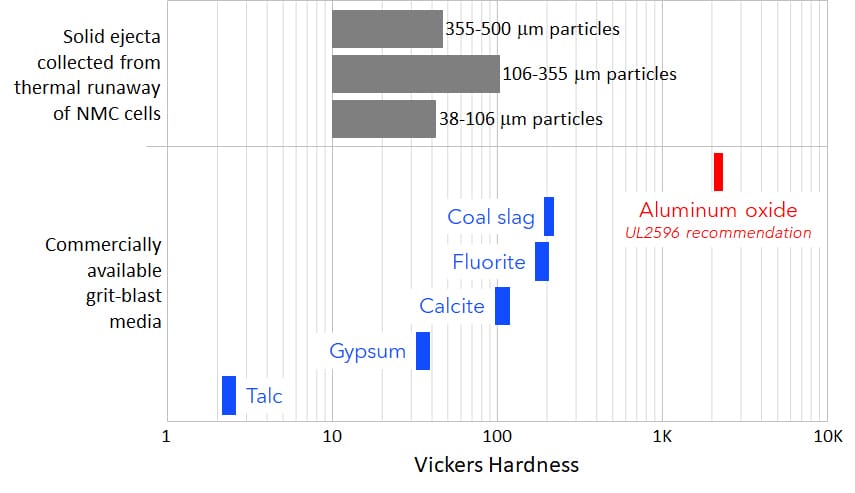

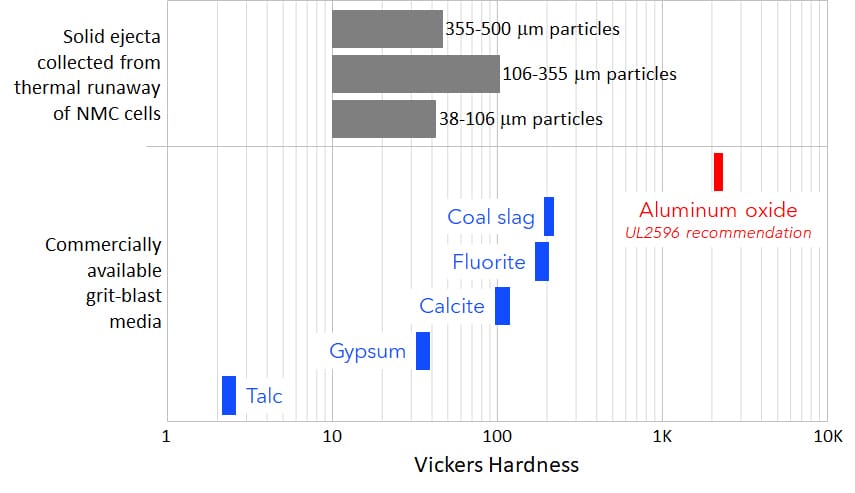

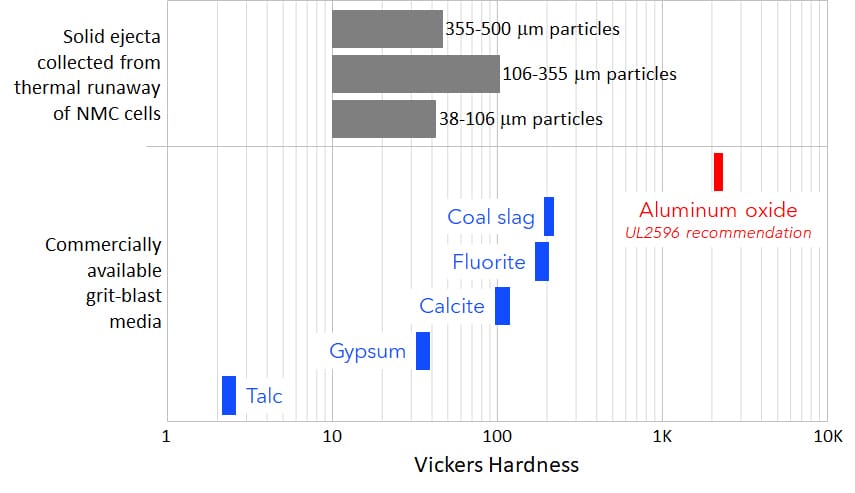

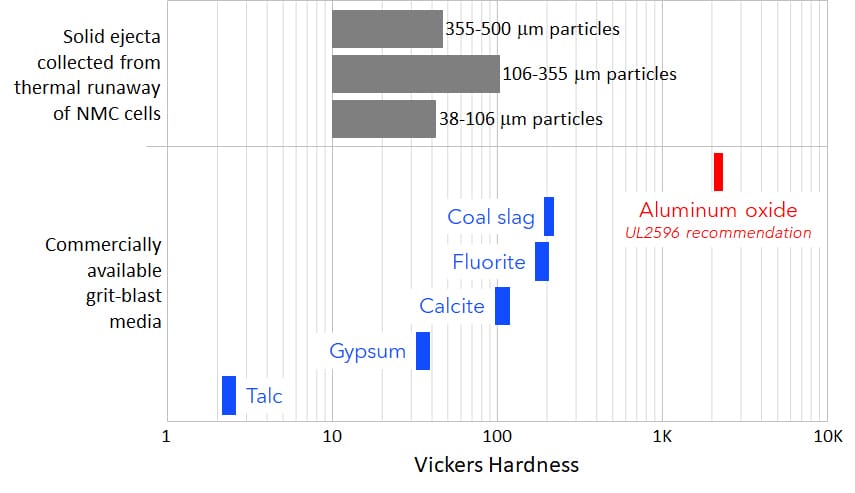

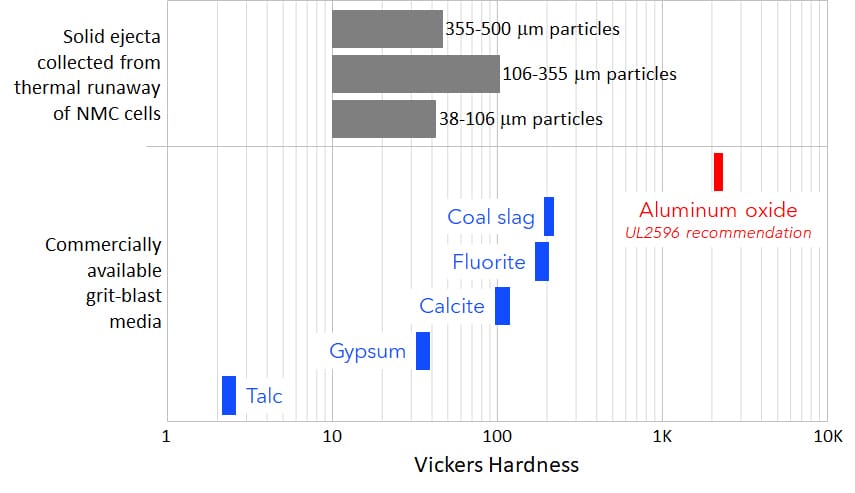

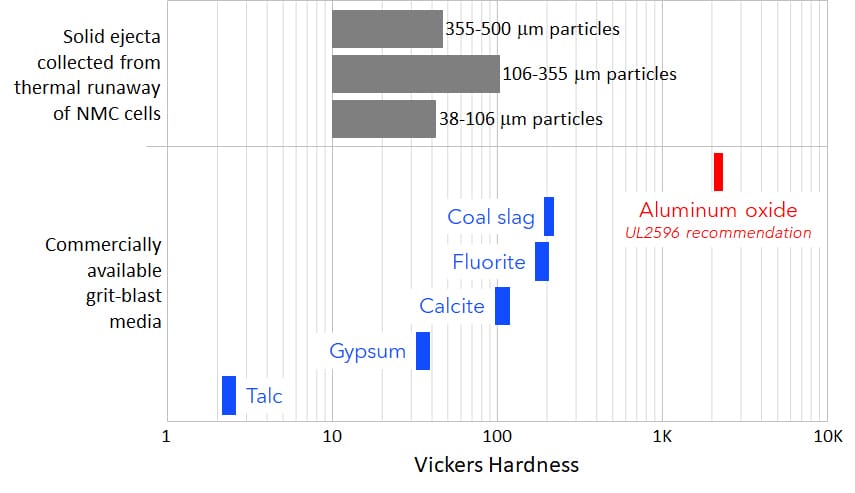

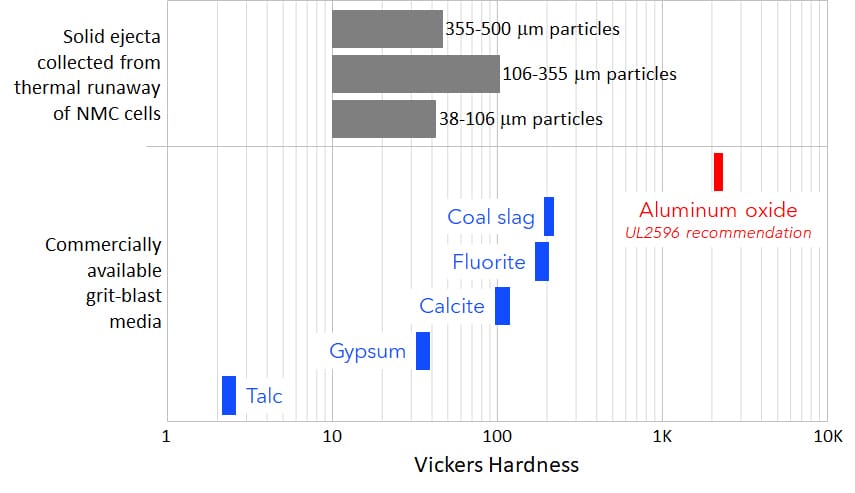

Smaller particles, possessing a Sauter mean diameter (D32) of 240 microns, were composed primarily of oxygen, aluminum, nickel, and carbon. Despite their metallic composition, these particles were soft and easily powdered in the hand. Vickers hardness testing was performed, showing most of the ejecta being significantly softer than UL 2596’s recommended grit, aluminum oxide. This suggests that further modifying the test with a softer abrasive would produce results more appropriate for surfaces outside the impingement zone.

Partner with scientists and engineers who deeply understand the complexities of thermal runaway events. Visit our website to learn more about PyroThin® cell-to-cell barriers and request a meeting with our technical team to discuss your application.