Lucid quadruples size of its Arizona assembly plant for Gravity SUV launch – Charged EVs

While sales of the Air sedan have been slow, Lucid is planning much greater capacity for the Gravity, a three-row luxury SUV with 440 miles of range.

Startup electric-car maker Lucid Motors cut the ribbon Wednesday on a massive expansion of its U.S. assembly plant in Casa Grande, Arizona. The company has built the Lucid Air luxury sedan there for about two years, but the enlarged plant is needed for production of its second EV, the Gravity three-row SUV. First vehicles are to be delivered before the end of this year.

Unveiled last November, the Lucid Gravity adapts the low, sleek, aerodynamic shape of the Air into an entirely different segment: the family SUV. With almost exactly the footprint of an Audi Q7, the Gravity offers 112 cubic feet of interior volume, close to the 121 cu ft of a Cadillac Escalade—a truck-based SUV more than a foot longer than the Lucid.

The company has adapted several key elements from the Air to create the Gravity, simplifying some aspects of the technology to reduce complexity and cost. While its battery case is shaped differently, the Gravity uses the same the 2170-format cells and modules as the Air. Its powertrain—comprising the motor, drive unit, and power electronics—has roughly 90 percent of its components in common with the Air.

The chassis is similar to that of the Air, though the changes required for its taller stance and higher body structure were sufficiently comprehensive that Lucid dubs it a new platform. Among those is the addition of air suspension, not offered on the Air sedan, but now essentially a required feature on load-carrying top-end luxury SUVs.

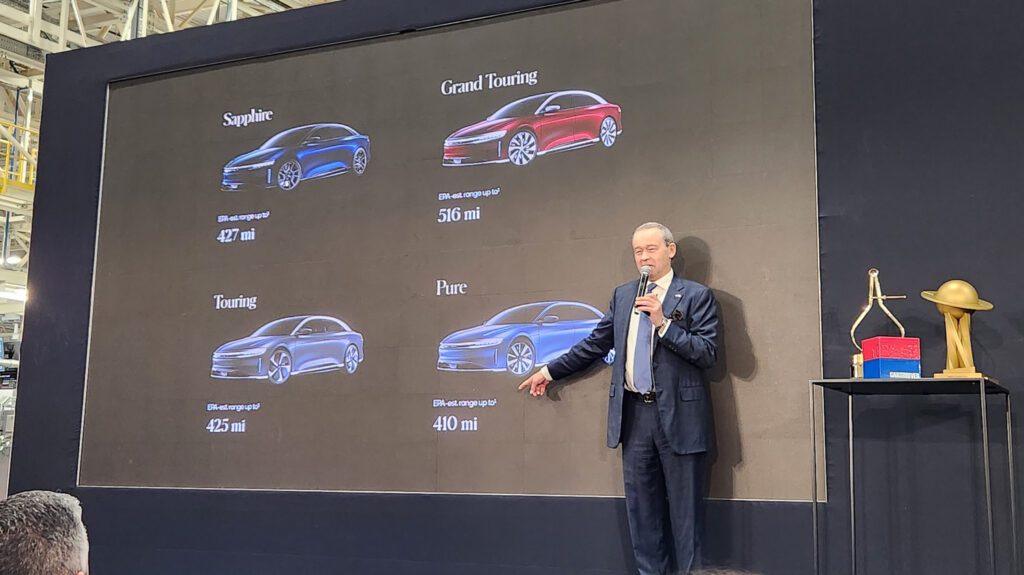

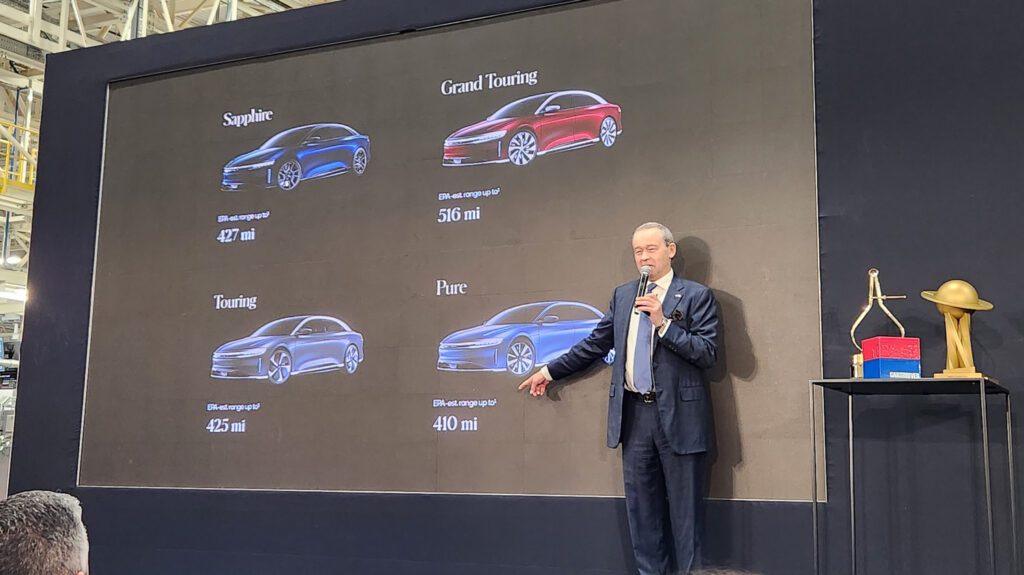

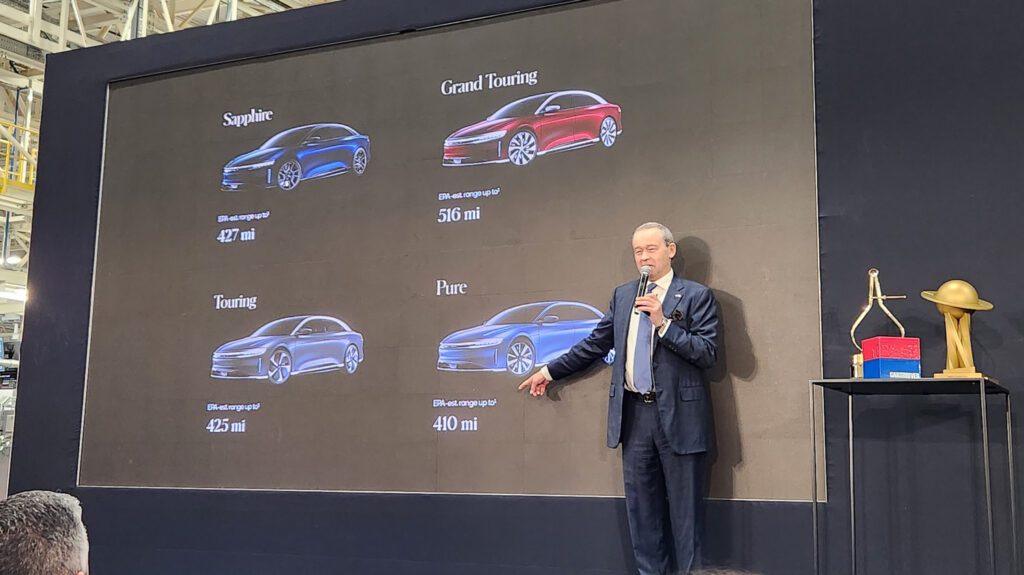

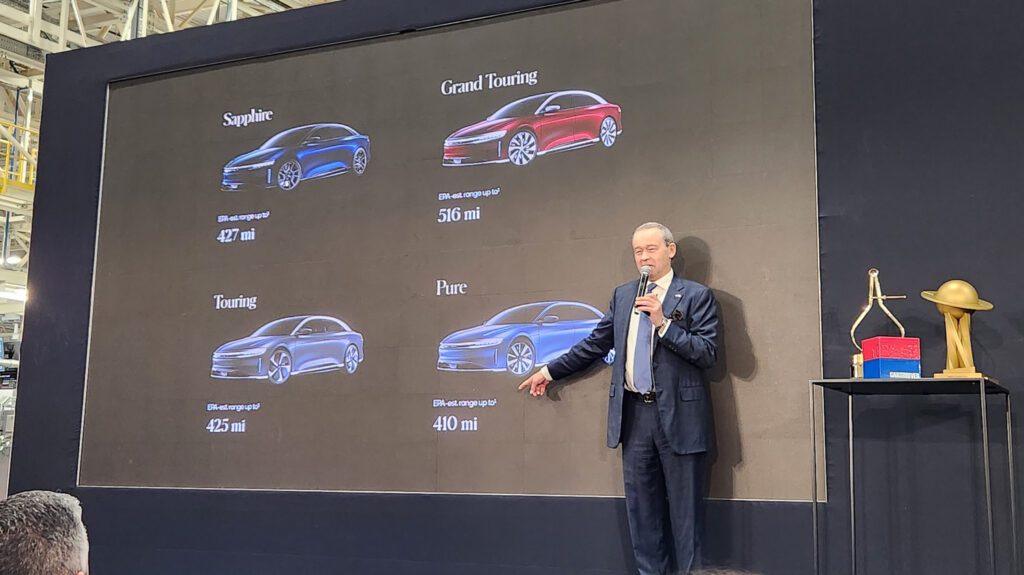

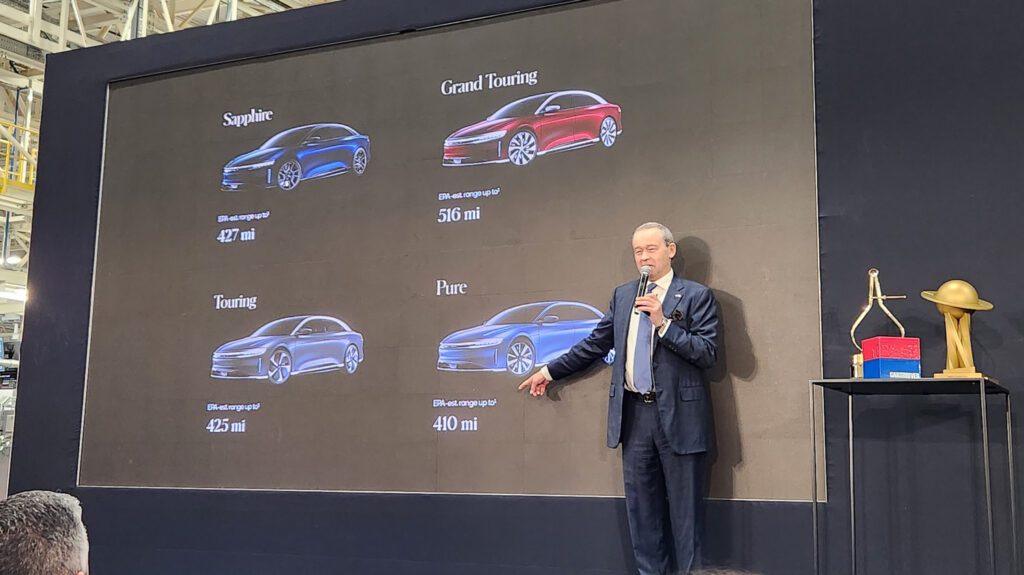

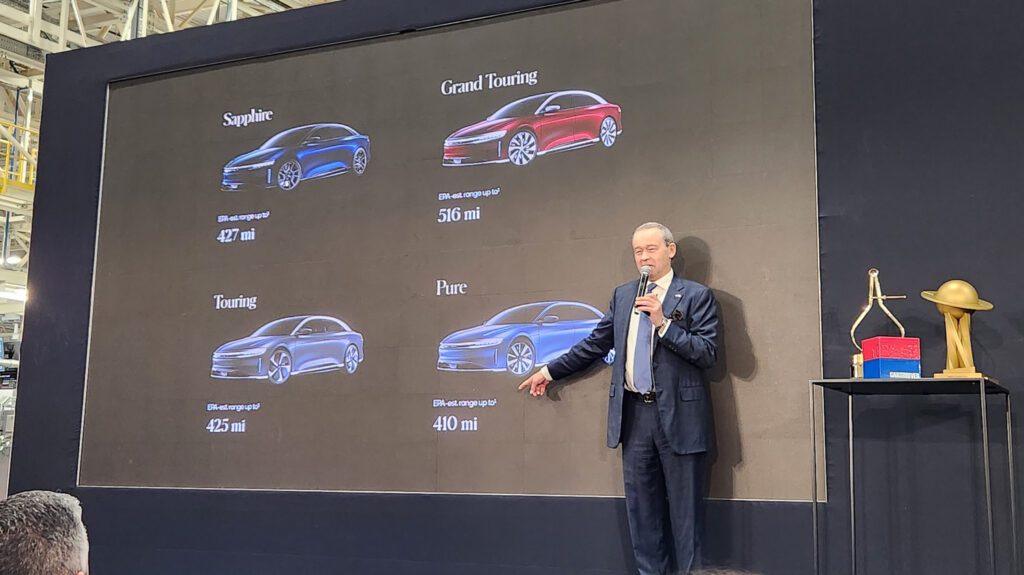

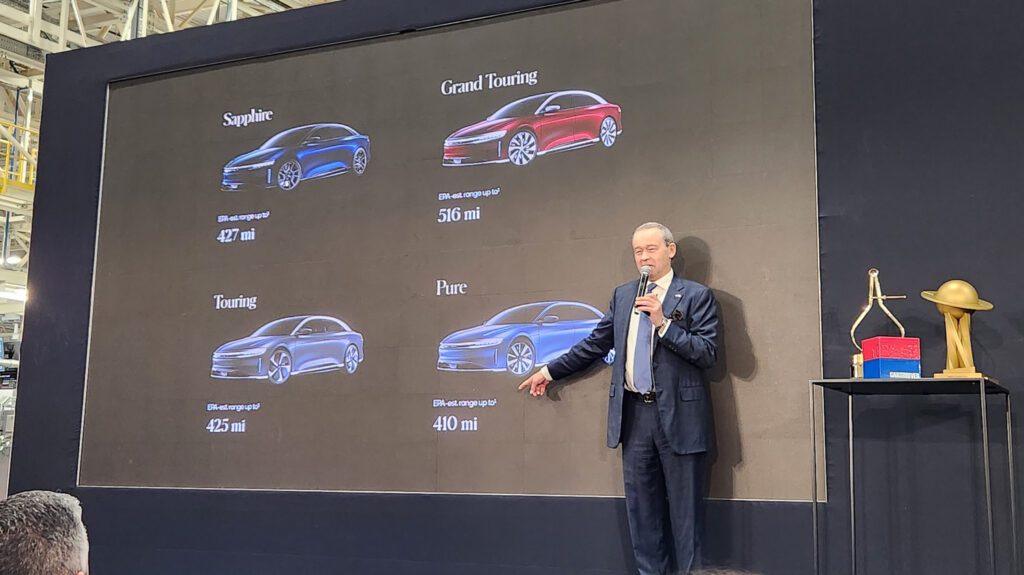

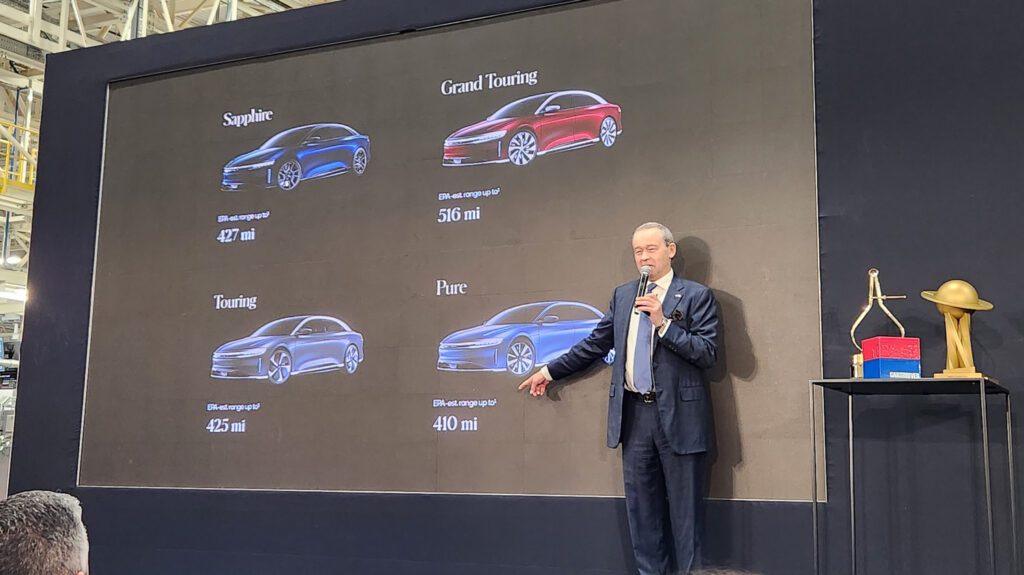

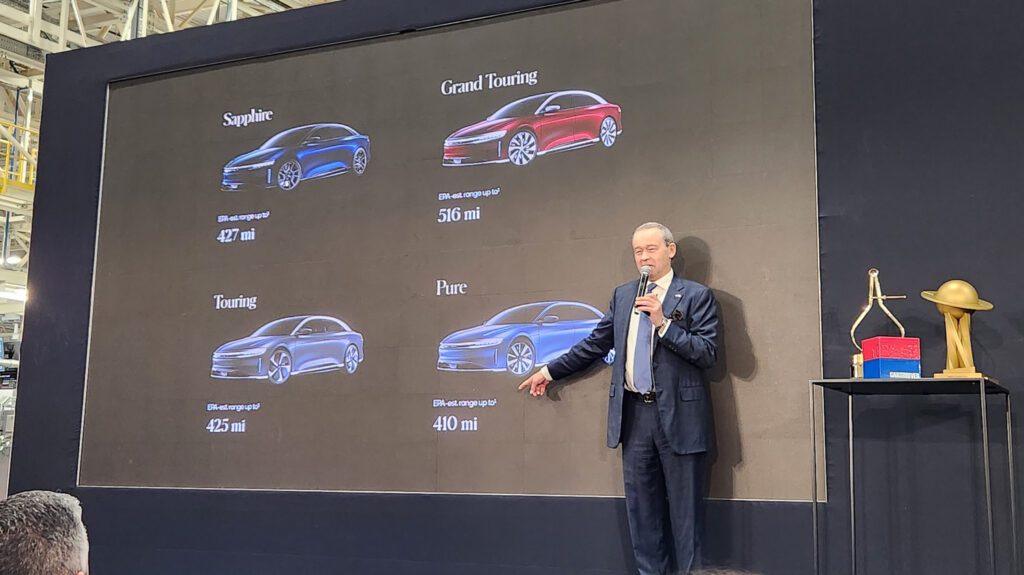

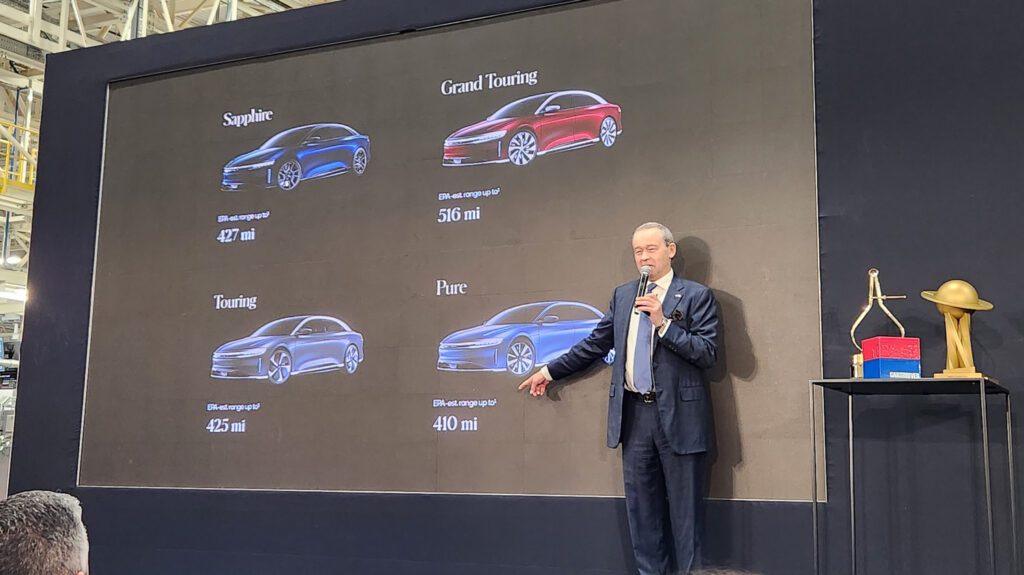

On launch, Lucid said, the Gravity will offer a rated range of 440 miles or more. While not as high as the 516-mile range rating for one specific version of the Air, that’s substantially more than the 348 miles offered by the longest-range Tesla Model X—or, as Rawlinson put it, “our closest competitor, whomever that may be.” A decade ago, Rawlinson was lead engineer on the original Tesla Model S, but there’s seemingly little love lost between him and his former employer.

More space, higher run rates

The factory in which production of the Air began in late 2021 was roughly 800,000 square feet in its first incarnation, and Lucid had to put some operations in several other sites within a 15-mile radius of the assembly plant. The plant’s footprint has now grown to 3.85 million square feet, almost quadrupling its initial size.

The facility now includes a new general-assembly line, expanded body assembly and paint shops, a new quality center, a warehouse, a logistics center, and an expanded powertrain facility that brings that function in from an offsite location. Finally, an advanced, vertically integrated new stamping facility will start operations later in 2024.

That first iteration of the Arizona plant (which Lucid calls AMP-1) had a run rate of six cars an hour, according to Steve Inglis, director of vehicle assembly. Once fully provisioned, he said, the expanded factory will be capable of producing up to 22 cars per hour—for a steady “customer yield” rate of 19 an hour, excluding stoppages, more intensive quality tests, any rework, and the like.

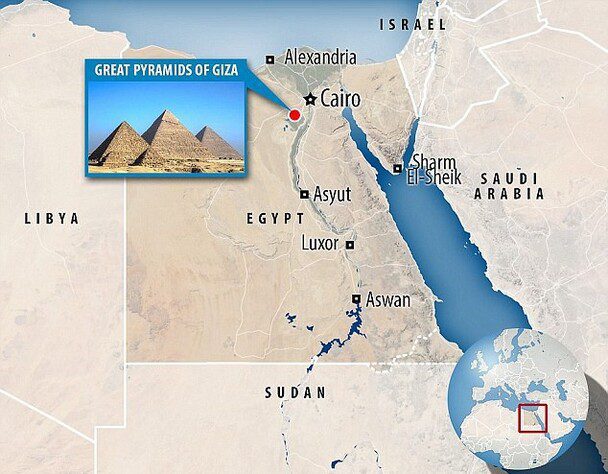

That translates to a maximum capacity of 90,000 cars a year. Even if the Gravity is a smash hit, that rate will take a few years to achieve. But Lucid has a second plant (AMP-2) going up outside Jeddah, Saudi Arabia, planned for a capacity of up to 150,000 vehicles a year. Today, the first section of that plant assembles Semi-Knocked Down (SKD) Lucid Air kits shipped from Arizona.

The Saudi Arabia plant will build Lucid’s third vehicle, a smaller SUV known only as ‘Project Midsize’—though it’s possible U.S. buyers might get versions built in Arizona that would qualify for U.S. government purchase incentives. During the event, Lucid CEO and CTO Peter Rawlinson briefly flashed a slide of a ‘Project Midsize’ vehicle under a cover, and said it was now undergoing engineering reviews. Smaller, less costly, and higher-volume than the Gravity, you can view it as Lucid’s competitor to the world’s best-selling vehicle for 2023, the Tesla Model Y.

Speeches and politicians

The ceremonial event on Wednesday was attended by Arizona governor Katie Hobbs, among others local luminaries. Rawlinson joined politicians and executives on a stage set up in the center of the expanded plant to cut the ribbon in front of several hundred Lucid workers.

The CEO kicked off the proceedings by reviewing Lucid’s history, from its start a decade ago as Atieva to its October 2016 name change. He said its unexpected offer to supply batteries for the nascent FIA Formula E single-seat EV race series was sufficient proof of its technology that the Saudi Public Investment Fund chose to invest billions of dollars in Lucid. That let the company start production of the Air, ending a two-year hiatus while Rawlinson sought funding.

Steven David, the plant’s SVP of manufacturing, then spoke at length about the plant’s goals of excellence and the company’s pride in operating Arizona’s sole auto assembly plant. He lauded the workforce, exhorting them and guests to make today the “Best Day Ever.”

In a first for this reporter, David spoke for longer than the two politicians who followed him put together. Governor Hobbs promoted the state’s growing ecosystem of sustainable and EV suppliers, while Congressman Juan Ciscomani—in whose district the plant lies—confessed his desire for the Arizona-built seven-seat Gravity, noting, “I’ve got five kids!”

Lucid provided airfare, lodging, and meals to enable Charged EVs to bring you this first-person report.